Smart manufacturing

Cradle-to-cradle product design and manufacturing for flexible and resilient manufacturing.

We focus on smart manufacturing: flexible, automated, digitised, high-quality and people-oriented.

Cognitive and physical operator support

Our working population is ageing, and it is becoming increasingly difficult for companies to attract and retain sufficient qualified talent. That is why it is crucial to support employees both cognitively and physically, so that they can perform at their best.

Our technologies support:

- Personalised training;

- Efficient creation of digital work instructions;

- Promotion of operator well-being;

- Human-robot collaboration;

- Efficient measurement of skills.

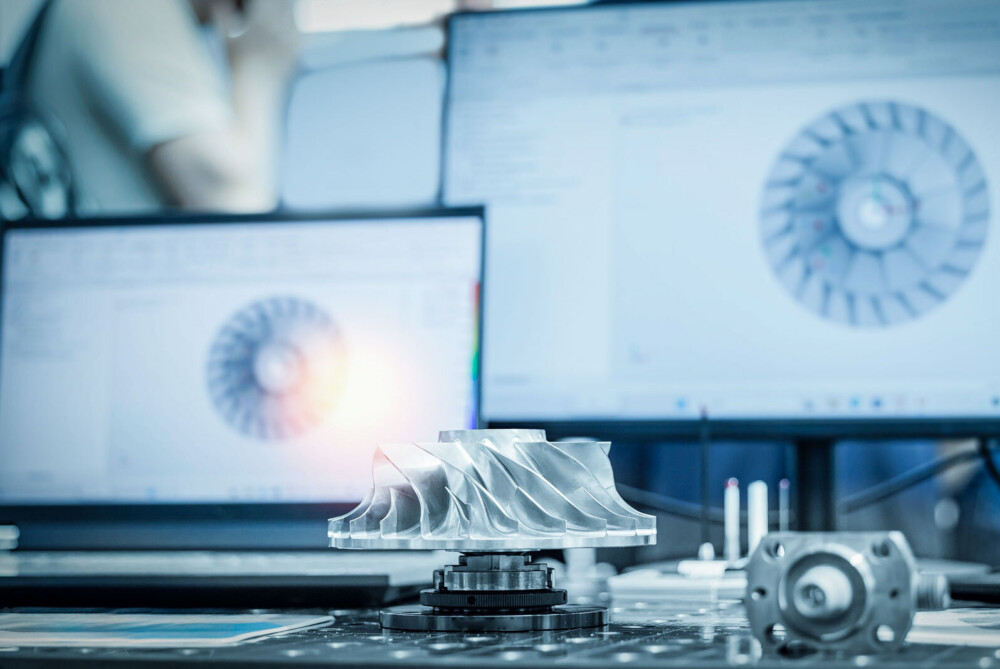

Zero-waste production

Production environments often generate a lot of waste, ranging from production process residues to packaging materials. By focusing strongly on improving the quality of their processes, companies can minimise their waste.

Our technologies support:

- Design for manufacturing;

- First-time-right production;

- Quality assurance and control during the production process;

- Efficient, image technology-based quality control.

Total Cost of Ownership optimisation

Companies require flexible automation that robotises high-mix production tasks quickly, accurately and affordably.

Our technologies support:

- Automatic robot (re)programming;

- Virtual development to increase robustness to domain variation;

- Flexible part manipulation;

- Flexible automated disassembly.

Efficient and resilient production

Companies need a factory-wide reasoning layer that brings together data and models to increase efficiency and resilience.

Our technologies support:

- Optimal Scheduling & Planning

- What-if scenarios & root-cause analysis

- Factory layout & simulation

- Supply chain management

Get in touch with our expert

Sales Manager at Flanders Make

Want to join our community?

As a member of Flanders Make, you gain access to a research team of over 1,000 experts who help shape your innovation journey.

You also receive priority access to the results of our research projects, and you are the first to know what is emerging and which topics will dominate tomorrow’s research agenda.

Our vision and context

The future of manufacturing

Global trends – such as erratic supply chains, growing demand for customisation and the relocation of production to low-wage countries – are radically changing the landscape of the manufacturing industry. At the same time, geopolitical pressure to produce more locally is increasing.

This is leading to two parallel movements: the rise of distributed micro-factories that offer agility and local responsiveness, and the growth of mega-factories that maximise economies of scale.

To remain competitive and local, factories must be able to respond rapidly to both predictable and unexpected changes. From new product introductions and rush orders to scaling up and down and disruptions in the supply chain. At the same time, they must be resilient to global challenges such as fluctuating raw material prices, material shortages and an ageing workforce.

The key to this transformation lies in production systems that are flexible, automated, digitised, high-quality, sustainable and people-oriented.

Cradle to cradle product design & manufacturing

- Engineering – Designing products for flexible manufacturing and demanufacturing.

- Suppliers – Creating supply chains that are resilient to both expected and unexpected changes.

- Manufacturing – Developing processes that are flexible, automated, digitised, high-quality, and human-centric.

- ReX – Enabling optimal product lifecycle management with flexible and automated de-/remanufacturing.

Manufacturing in detail