Smart and flexible quality control

Challenge

Smart quality control for customised production

Quality control for customised products is complex and time-consuming. Manual inspections are unsustainable when there is high variation and large volumes, while customers demand ever higher quality. Atlas Copco sought a more efficient, consistent solution that works within the production line.

Technologies

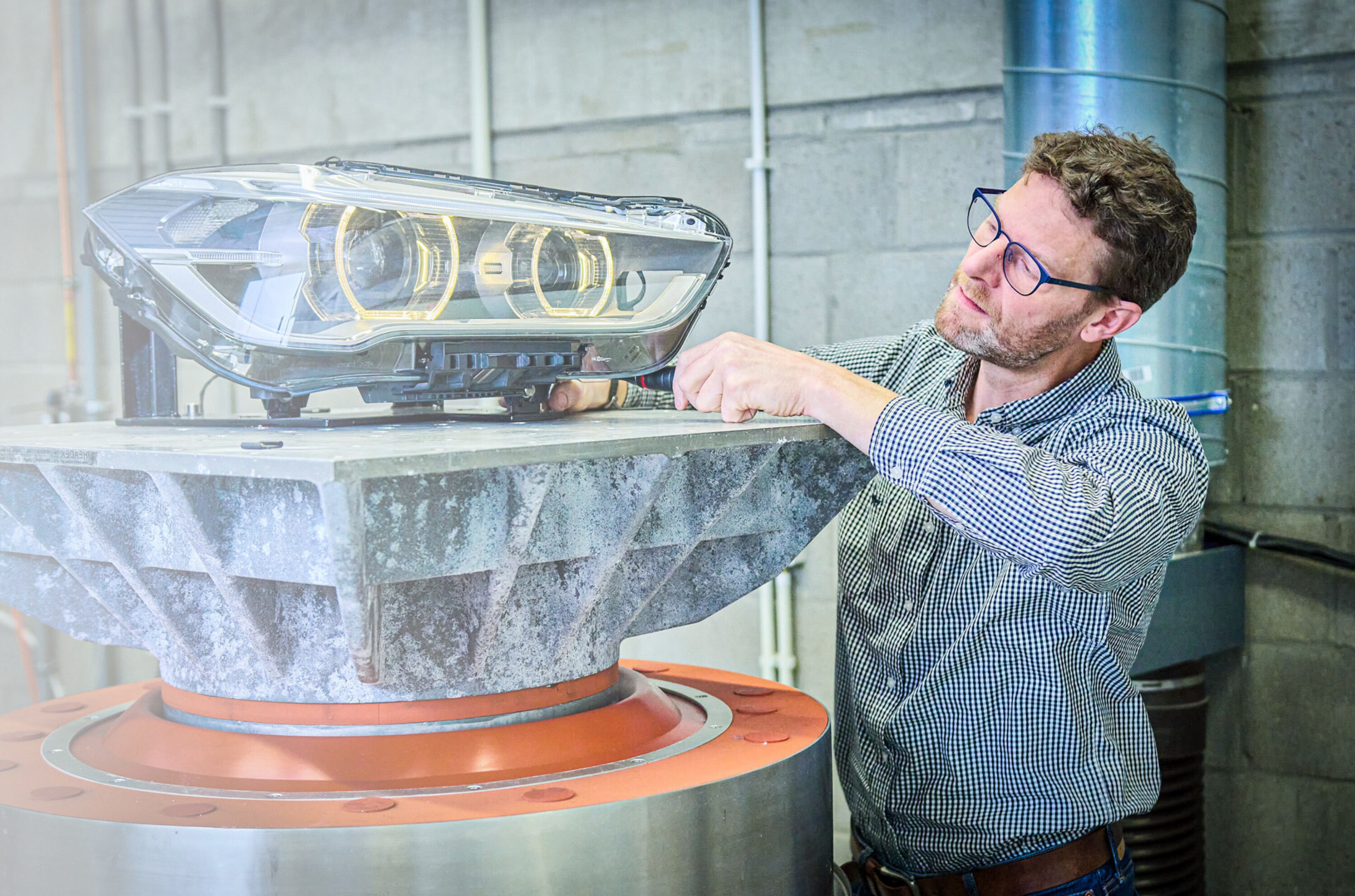

Flexible inspection with cameras

Together with Flanders Make, Atlas Copco developed a technology that optimally positions inspection cameras for different product classes. The configuration is easily adaptable, allowing new product lines to be quickly integrated without downtime.

Situational and self-awareness technologies

To identify, interrogate, and evaluate both environmental conditions and system states.

Result

Better quality, lower costs

The technology is now used for rotor inspection, resulting in fewer manual checks, higher product quality and a longer service life for compressors. In addition, Atlas Copco is achieving significant time and cost savings.