Process industry

From raw to finished material and back while reducing energy consumption and material waste

We focus on maximum productivity and resilience, efficient use of energy and materials, and a stable and optimal production process.

Production balanced with demand, capacity and costs

Make products efficiently and at the best time

Companies in the process industry depend on variable energy prices, the availability of (green) energy and access to (recycled) materials. At the same time, they need to be highly flexible and agile. With our advanced planning and scheduling technologies, we support them in producing the right products, at the right time, in the right quantities and at the lowest possible cost.

Sustainable production

Meet high customer expectations

Companies are facing increasingly stringent regulations and rising energy costs. At the same time, they need to reduce their CO₂ emissions, limit waste and work more with recycled materials. We offer them technologies that enable them to meet these requirements. This allows them to reduce their costs, limit their environmental impact and comply with both regulations and the high demands of their customers.

Production excellence

Work efficiently in complex conditions

Production environments are often complex and require multi-objective process optimisation. Stable product quality and maximum reliability and availability of production resources are of paramount importance. Our technologies enable advanced process control, increasing efficiency and allowing operators to work more independently. We also offer technologies that enable predictive maintenance and anomaly detection.

Strong employees

Strengthen and share expertise

Companies are facing a shortage of skilled workers, high labour costs, and on top of that, the challenge of retaining expertise and sharing it internally. Our technologies make it possible to capture and share expert knowledge so that all employees have the right information at the right time and in the right format for the task they are performing.

Get in touch with our expert

Sr. Sales Manager at Flanders Make

Want to join our community?

As a member of Flanders Make, you gain access to a research team of over 1,000 experts who help shape your innovation journey.

You also receive priority access to the results of our research projects, and you are the first to know what is emerging and which topics will dominate tomorrow’s research agenda.

The process industry: the silent engine of progress

The process industry is more than the backbone of the global economy – it is the silent force that drives our modern way of life. It provides the fuels that move us forward, the medicines that heal us, the materials with which we build our cities and the food that keeps us alive. All over the world, the process industry is driving progress.

This vital sector faces major challenges. Shifts in demand, market fluctuations, stricter environmental and safety regulations, an ageing workforce, outdated facilities and growing operational challenges are all converging. Society, regulators and markets are united in their expectations: we must achieve more with fewer resources – and in a more sustainable way than ever before.

Advanced and integrated digital solutions are leading the way forward. They help the industry respond strongly to these challenges and strengthen both profitability and sustainability.

From raw to finished material, and back

- Natural Resource Extraction: Mining, harvesting or drilling to extract raw natural resources.

- Purification & Refining: Removing impurities and improving quality for further processing.

- Primary processing: Converting raw materials into semi-finished products for production.

- Secondary processing: Processing semi-finished products into finished products that are ready for consumption.

- Use & End-of-Life: Products are used by consumers until the end of their lifecycle.

- Recovery & Recycling: Recovering waste products and recycling them into secondary raw materials.

Processing in detail:

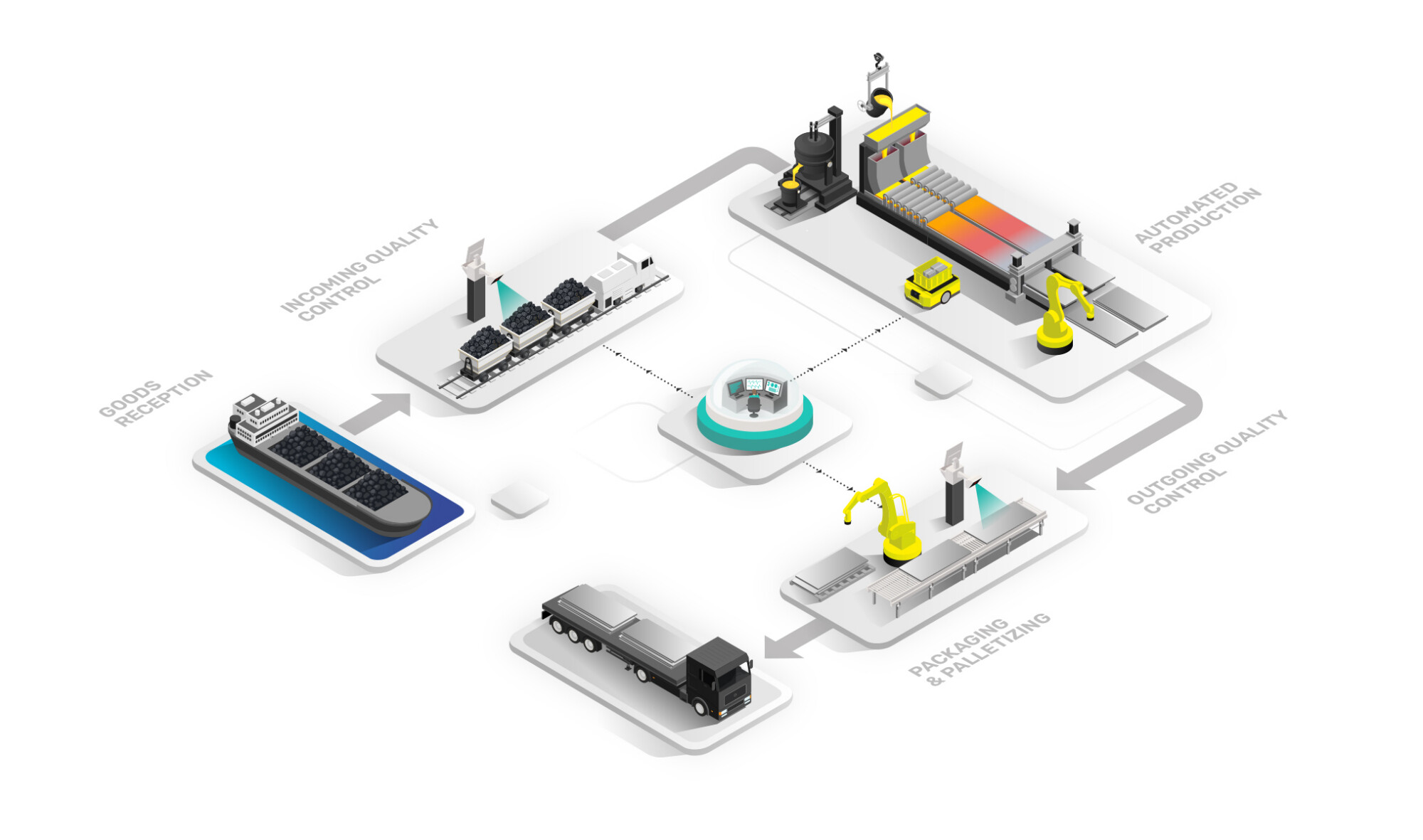

Automated production

The use of technology and machines to perform manufacturing processes with minimal human intervention, increasing efficiency and consistency.

Related success stories and technologies

- Pedeo used robotics, sensors and actuator technologies to connect non-smart machines via open standards.

- Bewel used our Employee 5.0 technology to explore the possibilities of Augmented Reality in their production.

- BMSVision applied our Reasoning & Acting technologies to create a smart AI colleague for their production planners.