Selecting the Right 3D Scanning Technology

3D scanning has become an important enabler for modern industry. It supports quality control, reverse engineering, digital twins, fast inspection, and process acceleration across sectors such as additive manufacturing, automotive, medical applications, large-component inspection, construction, logistics, agriculture and healthcare.

Because scanning needs vary widely—based on product geometry, material, surface properties, and accuracy requirements—selecting the right technology can significantly influence performance, cost, and overall workflow efficiency. Helping companies make informed choices is therefore essential.

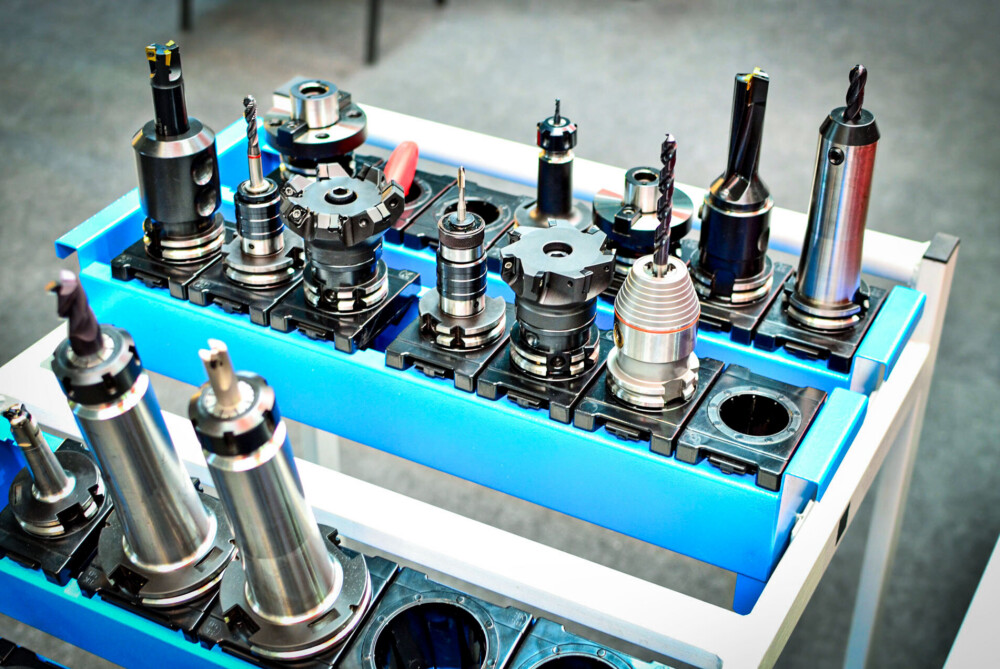

Available Scanning Technologies

The market offers a wide range of solutions:

- Coordinate Measuring Machines: highest accuracy, less flexible

- Fringe projection scanners: fast and detailed surface capture, sensitive to reflective or transparent surfaces

- Handheld laser scanners: portable and robust on tricky surfaces, operator-dependent

- CT systems: capture internal structures with high precision, limited by size and cost

- Other methods (stereo vision, photogrammetry…): accessible and scalable, but with lower accuracy

Bottlenecks in Industrial Scanning

Across industries, companies face recurring practical challenges when using optical scanning systems:

- Surface-related issues: shiny, reflective, dark, or transparent surfaces often require additional preparation or specialised setups.

- Complex geometries: multi-angle coverage demands careful scan planning and alignment strategies.

- Manual alignment and markers: many workflows still rely on physical markers or manual positioning to achieve reliable results.

- Time-consuming viewpoint selection: determining optimal viewpoints and ensuring sufficient surface coverage often depends on operator experience.

- Data handling and repeatability: consolidating multiple scans into a consistent dataset is labour-intensive and can introduce variation.

Achieving consistent and efficient visual inspection requires not only the right hardware but a solid workflow and automation strategy as well.

Automated, CAD-Driven Inspection

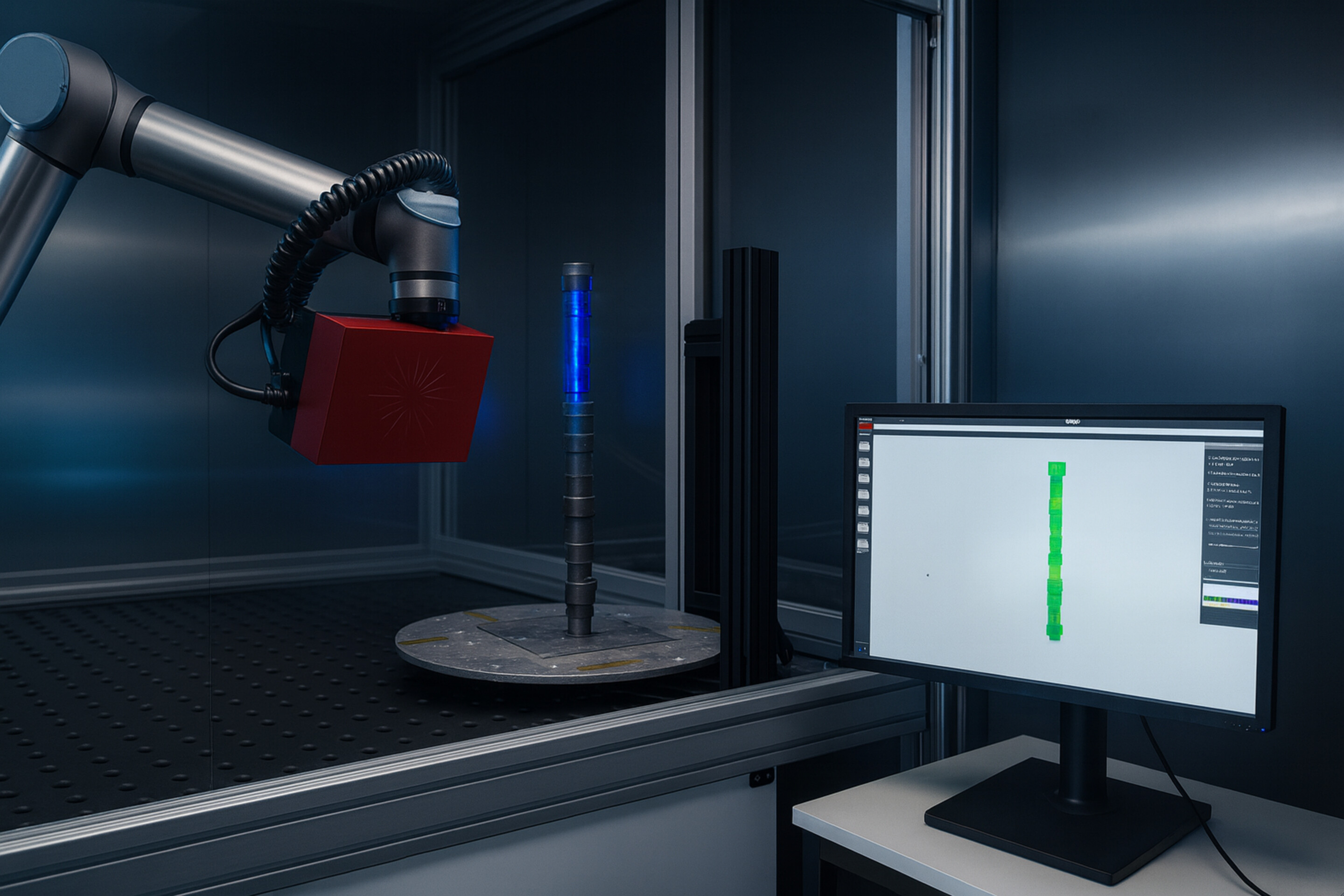

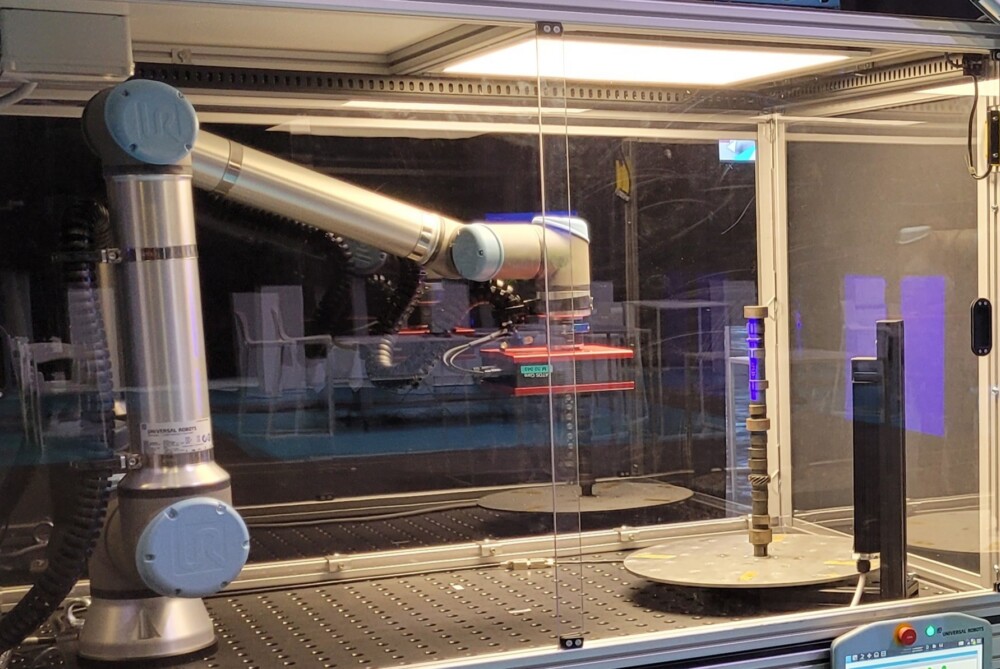

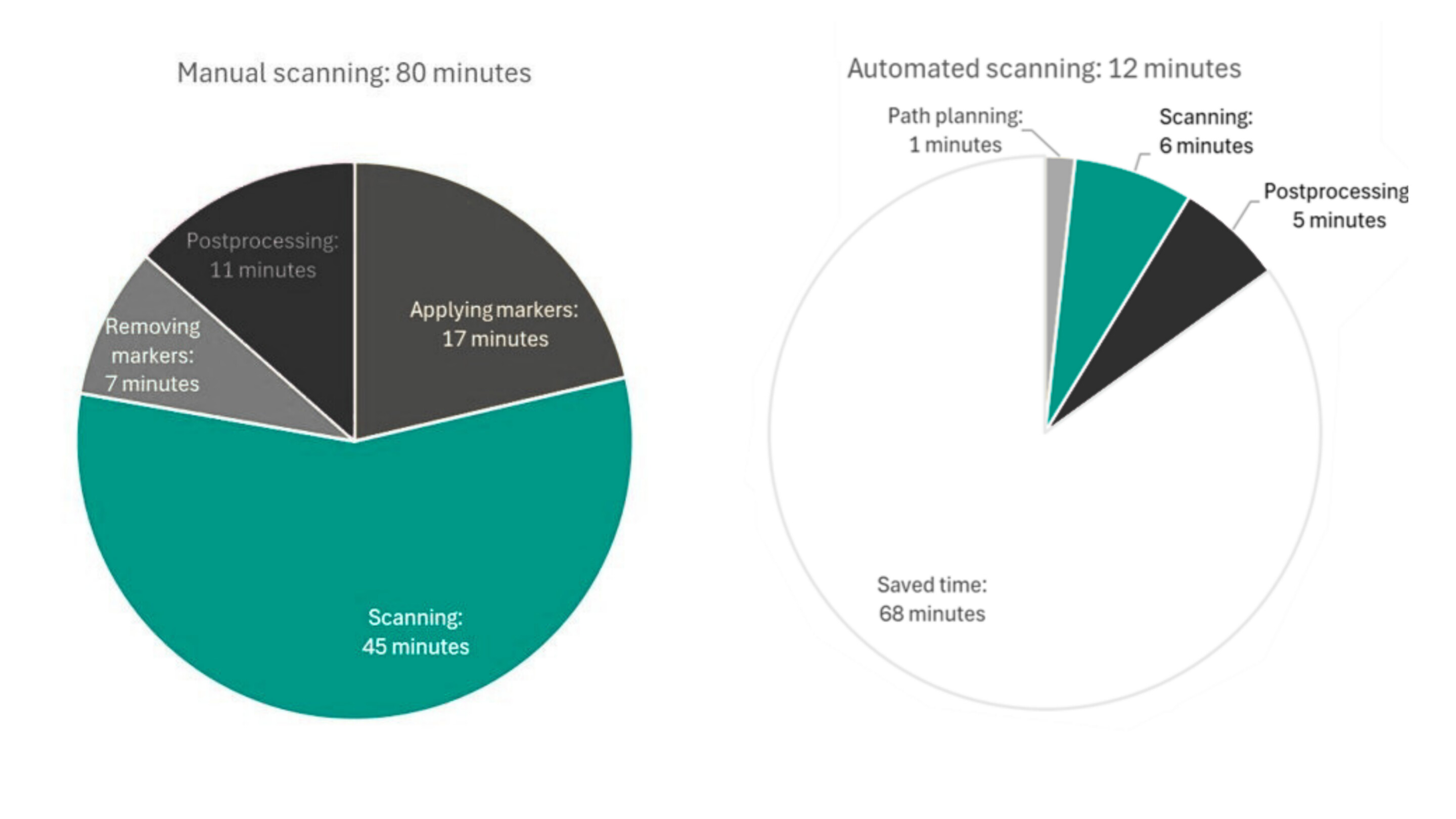

To help companies overcome these bottlenecks, Flanders Make develops methods that reduce manual labour and improve repeatability in 3D inspection workflows. Our research focuses on automating the full chain: from path planning to data fusion, based on the product’s CAD model.

Our modular framework enables:

- Automatic viewpoint optimisation: selecting the most effective viewpoints for robust, markerless scanning based on geometric features.

- Robot path planning: generating collision-free, efficient trajectories for different robot types.

- Automated data acquisition: coordinating scanners, cameras, and robot motion for consistent, repeatable scanning.

- Data fusion: combining multiple viewpoints into a coherent inspection result.

This approach supports different hardware configurations - multiple robots, various area scanners, and 2D camera setups - making it flexible and scalable for companies of all sizes.

Contact us for technology guidance and tailored solutions

Selecting and implementing the right 3D scanning technology is a strategic decision that influences quality, efficiency, and future automation potential. With a complex landscape of available solutions and many practical considerations—from surface challenges to scan planning—companies benefit from clear guidance and hands-on insight.

We can provide neutral support, practical demonstrations, and research-driven tools that help organisations compare technologies objectively and integrate automated inspection into their workflows. Our goal is to lower the threshold for adoption and ensure companies of all sizes can select solutions that truly match their products and processes.

This blogpost recaps the final event of the EU-funded project ACCUMONIT (Improving accuracy of CNC machines).