Improving accuracy of CNC machines

In this CORNET-COOCK project, we research innovative solutions for monitoring the workpiece-accuracy of CNC machines and other manufacturing process.

About ACCUMONIT

Precision machining is essential in manufacturing, but achieving high accuracy often conflicts with productivity—especially in small-batch production, where the risk of scrap increases.

The project aims to advance state-of-the-art monitoring of workpiece accuracy during machining and to improve subsequent automatic optical inspection.

Project goals

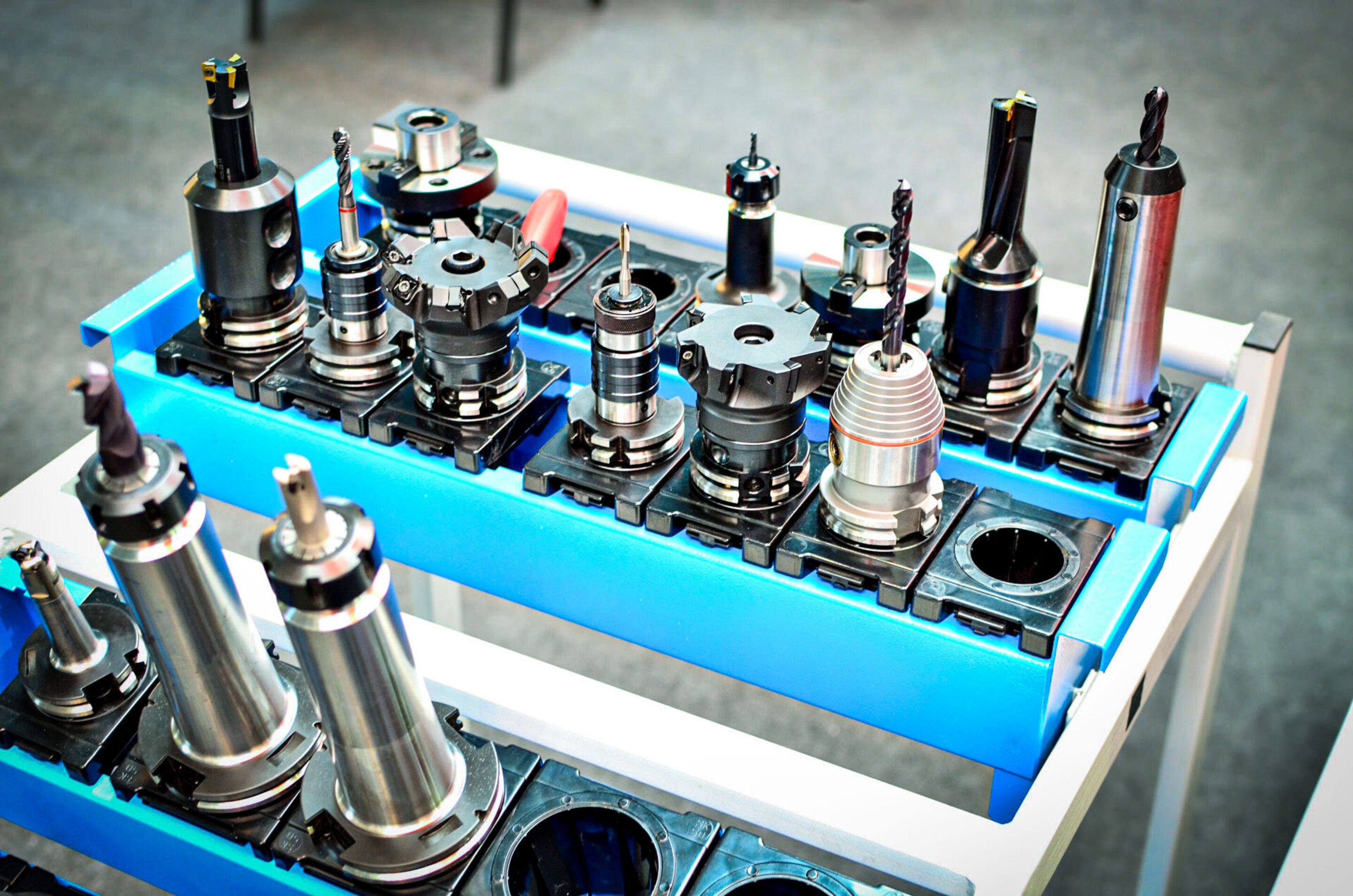

- IMU-based measurement system: Because CNC machines lack sufficient stiffness, encoder positions alone are not accurate enough. Inertial measurements near the spindle improve real-time tool pose estimation.

- Instrumented toolholder for cutting-force estimation: Cutting forces reveal process performance issues such as tool wear and bending. Combined with virtual sensors, they also enable accurate estimation of workpiece geometry.

- Fast 3D scanning near the machine: Automated, non-contact measurements increase the speed and accuracy of full workpiece inspection.

- Data-driven inaccuracy-decomposition tool: Machine-learning algorithms identify root causes of machining errors and separate different error contributions by learning complex dynamic relationships.

Blogposts

- Innovations for Visual Inspection

Vision technologies are revolutionising quality control through reliable visual inspection as well as streamlining the entire production process. - Selecting the right 3D Scanning Technology

We can help companies compare technologies objectively and integrate automated inspection into their workflows. - Accuracy Monitoring in der Metallbearbeitung (Fraunhofer, Duits)

By capturing machine and sensor data during the production process, we can identify and predict deviations between planned and actual workpiece geometry, thereby reducing traditional time-consuming quality checks. - Why Cutting Force Measurement Matters - And Why Proximity to the Tool Tip Is Key (KU Leuven)

Bridging physical manufacturing and digital intelligence to improve precision engineering, monitoring, and optimization of industrial production.

Videos

- Fast, automated 3d scanning for product inspection

This demo invites you to alter the geometry of a scanned product to see how quickly and easily our integrated approach of viewpoint optimisation and markerless point cloud registration for 3D scanning generates an accurate result. - Measuring cutting forces at the tool tip

This demo shows a clean, accurate method of measuring cutting forces close to the tool tip, and accurately estimating the ensuing geometry of the workpiece.

Would you like more information about this project?

Partners