Choosing the right planning software for your production

In an increasingly complex and competitive production environment, efficient planning is no longer a luxury but a prerequisite for maintaining performance. For many manufacturing companies, planning is a crucial lever to keep lead times under control, absorb disruptions and make better use of available capacity. At the same time, the range of planning software has grown significantly and become more diverse, making it increasingly difficult to assess which solutions truly fit a company’s specific production context.

Starting from this observation, we looked at the planning software market through the lens of the Flemish manufacturing industry. Not with the aim of identifying one “best” solution, but to support companies in making well-informed decisions. Matching specific business needs with the scope, benefits and limitations of different types of planning software is complex. This is where we can add value: by bringing structure to the landscape, setting realistic expectations and framing choices based on independent expertise.

The outcome of our analysis provides:

- an overview of the main types of planning software currently available;

- insight into their relevance and applicability for the Flemish manufacturing industry;

- a better understanding of how these tools address typical planning challenges such as capacity management, bottleneck detection, sequencing and KPI monitoring;

- recommendations for companies looking to strengthen their planning processes.

What types of solutions do we see in the market?

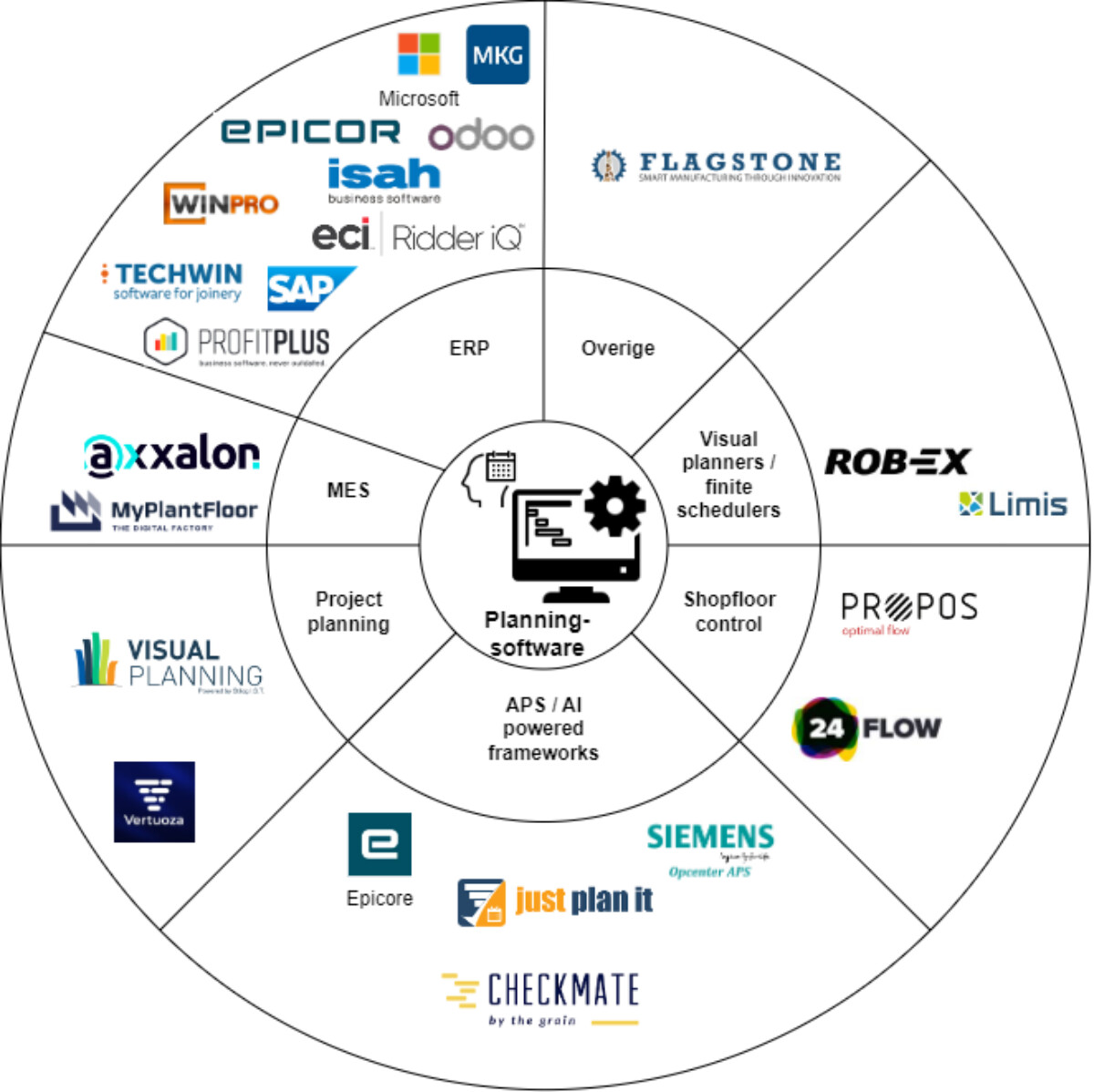

We observe a wide range of solutions, each with its own focus. To maintain clarity, we classified the tools based on their standard functionality. Many packages can be extended with additional modules or integrations, allowing them to fit into multiple categories.

The main categories are:

- ERP systems: enterprise-wide platforms that typically offer basic planning capabilities, often extendable with additional planning modules.

- MES (Manufacturing Execution Systems): systems focused on managing and monitoring production processes on the shop floor.

- Project planning tools: solutions aimed at project-based planning, usually less aligned with operational production planning.

- APS (Advanced Planning & Scheduling): specialised tools for advanced planning, optimisation and resource allocation.

- AI-driven planning solutions: an emerging category that uses artificial intelligence for forecasting, dynamic adaptation and optimisation.

- Shop Floor Control systems: tools that support and monitor the execution of production activities on the shop floor.

- Visual planners and finite schedulers: visual, often low-threshold tools for planning within fixed capacity constraints.

In addition, there are sector-specific solutions (for example for joinery), but our evaluation focused exclusively on generic planning functionalities. Companies are advised to take sector-specific requirements into account in their own selection process.

Evaluation framework: focus on planning functionality

To compare the different systems in a consistent and objective way, we developed an evaluation framework centred on core planning functionalities. This included, among others:

- capacity management and resource modelling;

- lead times and order sequencing;

- bottleneck detection and WIP (Work In Progress) control;

- KPI visualisation and delay signalling;

- support for S&OP (Sales & Operations Planning);

- capabilities for data-driven optimisation.

This framework allowed us to compare solutions independently of their commercial positioning or marketing message, with a clear focus on practical applicability in an industrial context.

Functional trends in planning software

The analysis reveals clear trends, depending on the type of solution:

- ERP systems remain the operational backbone for many companies and typically offer planning based on MRP logic. Their strength lies in integration with other systems, but advanced planning and bottleneck analysis often require additional modules or external tools.

- MES and shop floor control solutions provide detailed, and often real-time, insight into shop floor operations. They support rapid adjustments in response to disruptions and increasingly integrate heuristic or AI-based algorithms. Lean concepts such as Kanban and CONWIP are often available.

- APS and AI-driven tools strongly focus on optimisation, dynamic sequencing and simulation. They offer powerful visualisations but place high demands on data quality and integration with existing IT landscapes.

- Visual planners and finite schedulers are generally quick to deploy and user-friendly. They are mainly suited to smaller companies or less complex environments, but offer limited automatic optimisation.

- Dashboards and KPI monitoring have become almost standard, often with links to BI platforms such as Power BI.

Overall, integration between ERP, MES and specialised planning software is crucial. More advanced solutions offer additional optimisation potential but also require more data, discipline and expertise. AI is gaining importance, but in many applications it is still at an early stage.

Insights for a well-informed decision

Our analysis confirms that there is no universal solution for planning support in the Flemish manufacturing industry. The right choice strongly depends on the maturity of the organisation, the complexity of the production environment and the strategic vision for digitalisation.

Solutions that operate close to the shop floor, such as MES and shop floor control systems, often provide the most direct support for operational planning and enable rapid intervention. At the same time, they require robust integration with ERP systems, which entails additional investment and technical complexity.

Data-driven and AI-based planning solutions offer interesting opportunities for predictive planning and optimisation. Their added value, however, depends heavily on the availability of reliable and up-to-date production data. Without this foundation, their impact remains limited.

ERP systems continue to play an important anchoring role. Although their planning functionality is often less advanced, interfaces and APIs make it possible to connect specialised tools. This increases flexibility, but also requires careful consideration of costs, maintenance and long-term dependency.

For a successful planning solution, it is not only functionality that matters. Integration complexity, data quality and long-term scalability are equally important factors.

Find out more

Would you like to receive the full report? We'd be happy to share our comprehensive analysis and help you answer the questions that are important to your company.