From Diesel to Electric: Belgium’s First Certified Retrofit Truck Hits the Road

With our support, e-TROVA has delivered its first fully homologated diesel-to-electric retrofit truck, the first D2E-certified heavy-duty truck in Belgium. This achievement marks a turning point: the e-TROVA e-truck has officially moved from prototype to a certified product in operation, proving that retrofitting existing diesel trucks is a viable, fast-track solution for greener logistics. In this article, we celebrate this milestone that combines sustainability, innovation, and industrial impact. The future of transport isn’t only about new vehicles. It’s about giving existing trucks a clean, electric future. This is how we help set the pace for heavy-duty electrification in Europe.

We’ve proven that retrofitting can be both technically sound and economically viable. We’re enabling transport companies to accelerate their energy transition using the vehicles they already own.

Giving Trucks a Second (Electric) Life

Across Europe, heavy-duty trucks over 16 tons are responsible for nearly a quarter of total road transport emissions. The European Green Deal sets the goal of cutting emissions by at least 45% by 2030, but replacing diesel fleets with new electric trucks has proven slow and costly.

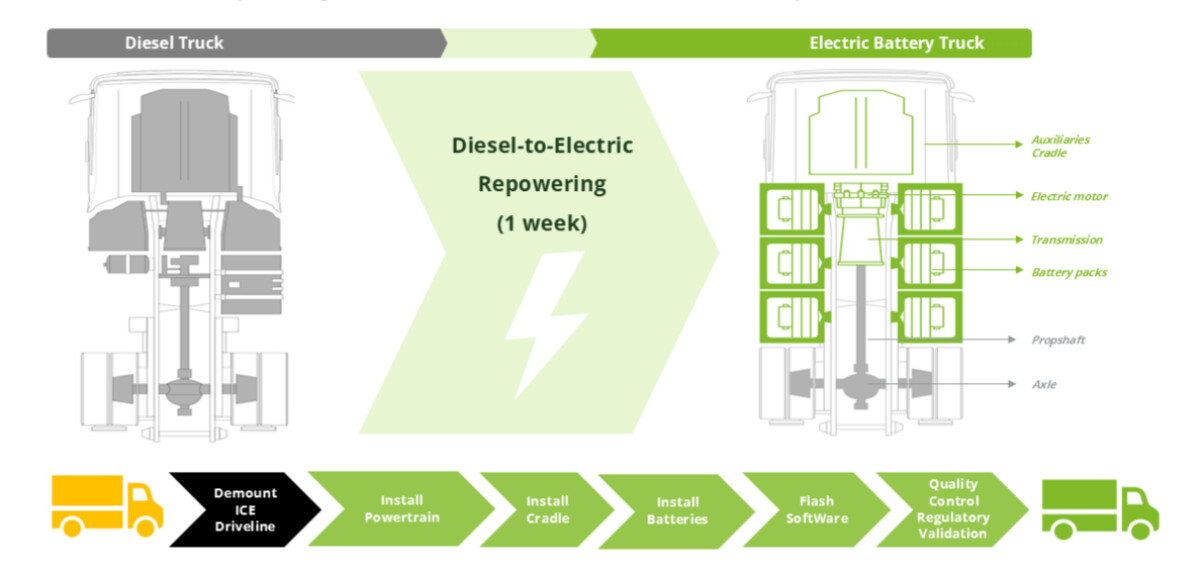

Our solution: a diesel-to-electric retrofit method developed together with e-TROVA. Instead of waiting years for new trucks, existing diesel trucks can be repowered with a fully battery-electric powertrain, extending their lifespan and cutting emissions immediately.

An innovative conversion

- 1 week effective rebuild time

- flexible battery configuration based on use-case of transporter

- multibrand approach for compatibility with different truck brands and models

- modular design to scale electrification efficiently and cost-effectively across fleets of all sizes

- and:

- 480km

UP TO 480 KM RANGE

From Digital Simulation to Real-World Truck

Behind this innovation lies a simulation and validation environment we developed. Engineers use this digital setup to test powertrain components, vehicle performance and control software before any physical build begins. This Model-in-the-Loop (MiL) environment allows faster, safer, and more efficient validation of vehicle control software, a key step in achieving D2E certification. The control software is designed to be brand-agnostic, managing everything from traction coordination and auxiliary systems to diagnostics, charging, safety and communication with the truck’s original ECUs.

Now that the first truck has been certified and delivered, the next chapter begins. Starting now, multiple trucks will be built, and the compatibility of the powertrain and control software will be validated across additional brands and models.

This isn’t just about one truck. It’s about creating a repeatable, efficient process that any fleet operator can adopt. Every retrofit truck helps reduce emissions and keeps valuable materials in use.

Innovation through collaboration

Our partnership with e-TROVA demonstrates how collaboration between research and industry can turn innovation into real-world impact.

Contact us today for your journey to sustainable innovation.

On Tuesday December 2nd Nick De Bie (Flanders Make) will present this story at CTI Symposium. Join us at this event for the latest developments, innovations, information, solutions and new contacts in the powertrain and mobility industry.