Connecting non-smart machines with open standards

Challenge

Old and new machines in a single network

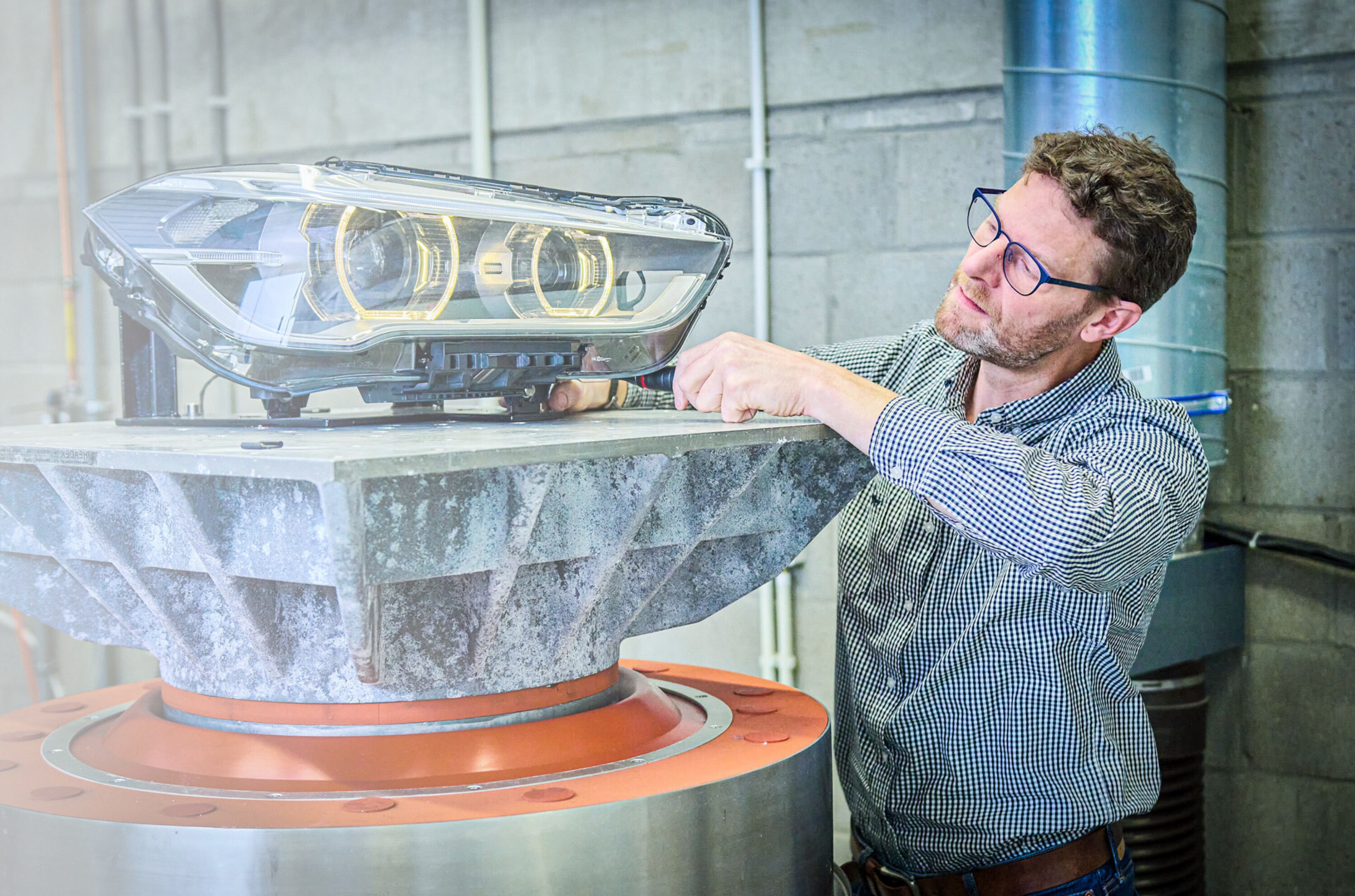

At high-pressure foundry Pedeo, not all machines could be connected to their Manufacturing Execution System (MES), with older models and equipment from different manufacturers proving particularly difficult. Together with Flanders Make, they sought an open, affordable way to integrate all machines into the network.

Technologies

Open standards as the key

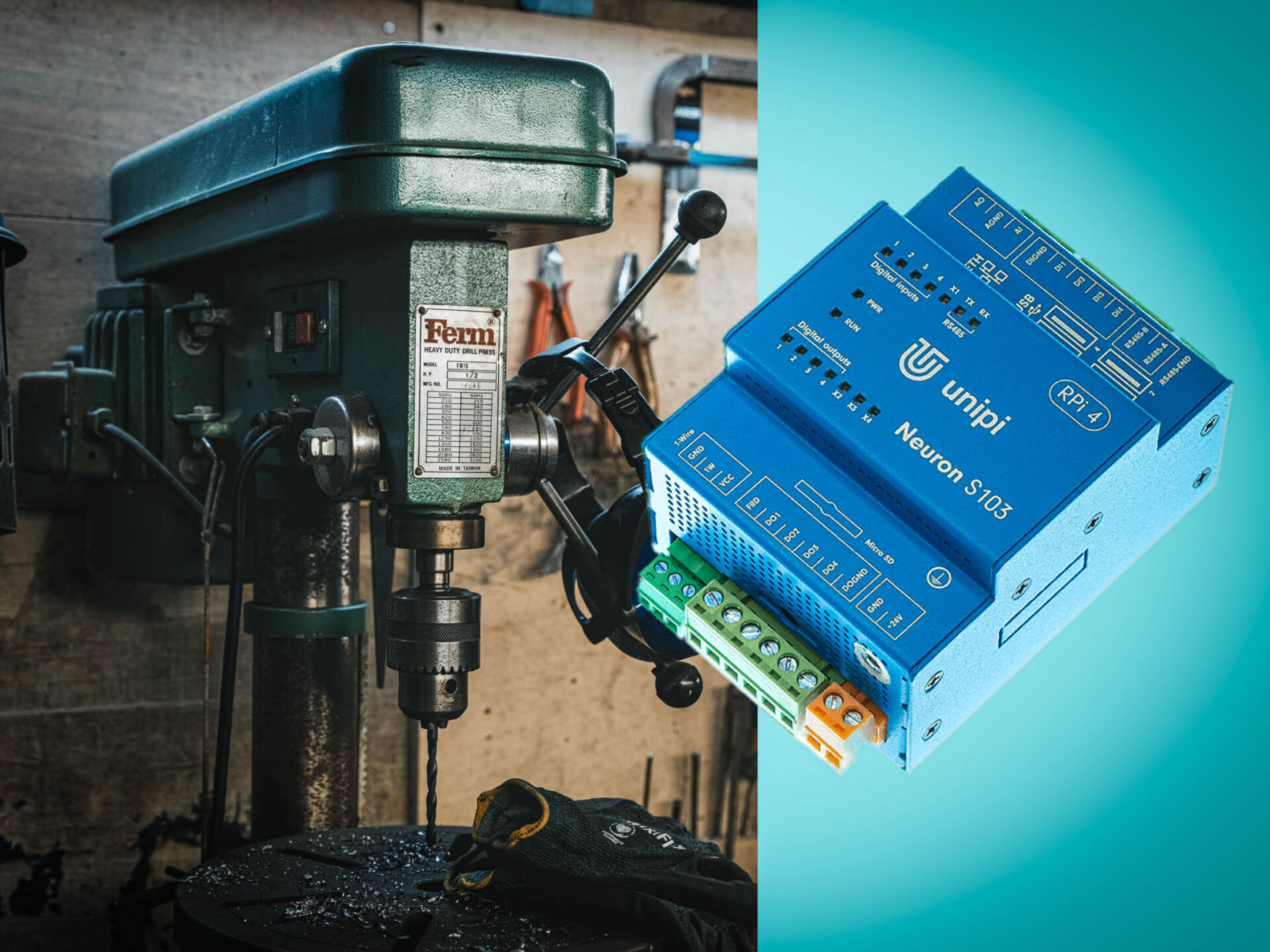

Using a Unipi, a versatile, affordable device that can process digital and analogue signals, machines were connected via open source software to the OPC-UA protocol, an open communication standard. As proof of concept, a robot cell was successfully connected to the MES.

Robotics, sensors and actuators

Improving the core components of robotics and smart machines.

Result

Scalable and shareable

The system is widely applicable: in theory, virtually any drill, press or automation system can be integrated in this way. A manual was also drawn up so that other companies can easily implement similar connections.