Automating stator placement for ELNOR Motors

Challenge

Cobot and vision system improve motor production

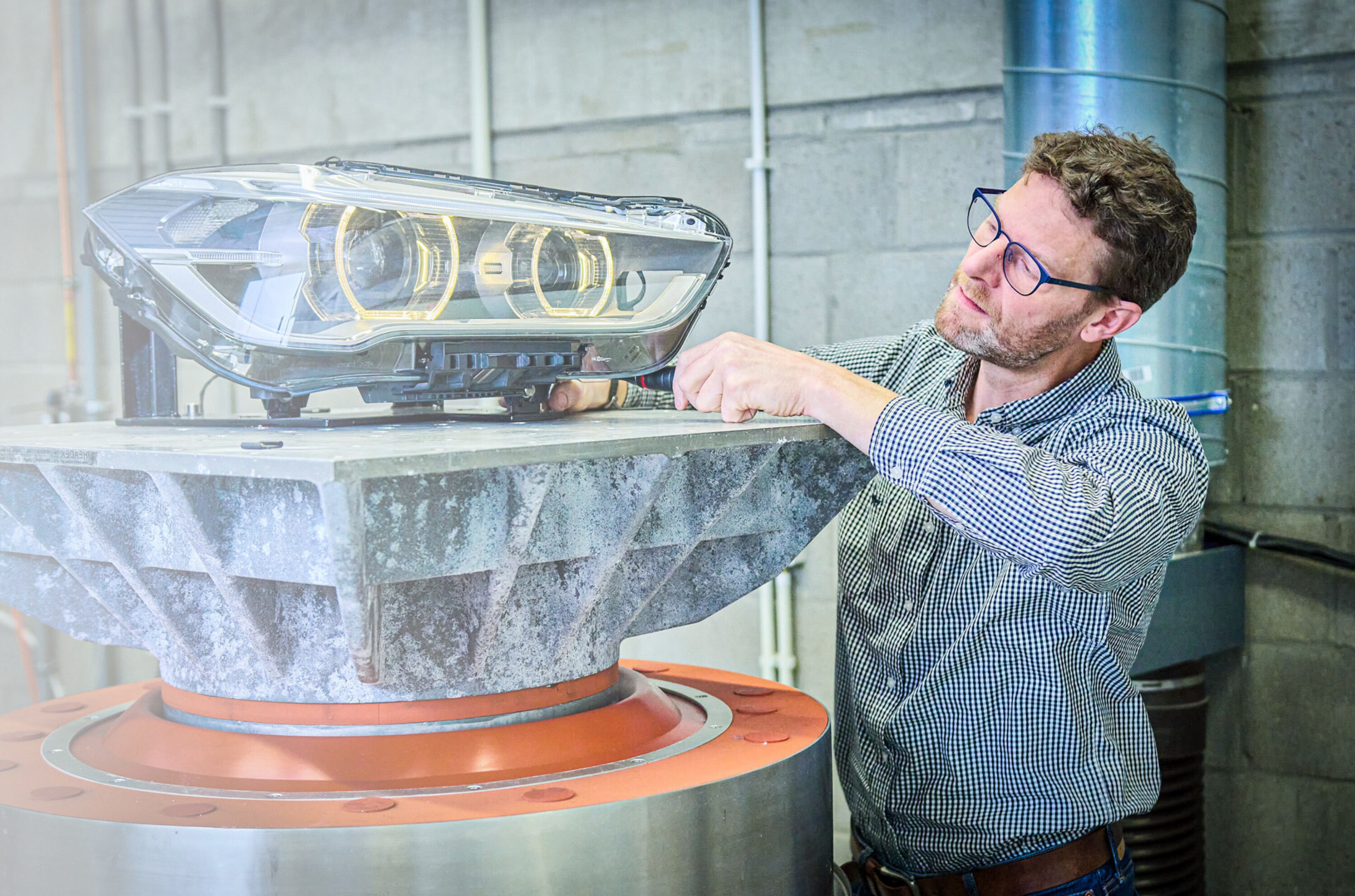

ELNOR Motors has been developing customised electric motors for over a century. Until now, placing stators for slot insulation was a repetitive and physically demanding task that also required visual inspection. Together with Flanders Make, research was conducted into how this step could be automated.

Technologies

Combination of power and precision

A cobot safely moves the sometimes heavy stators, while a 2D vision system takes over the visual inspection and checks whether the stator is correctly positioned. This makes the process more consistent and less dependent on physical effort by the operator.

Situational and self-awareness technologies

To identify, interrogate, and evaluate both environmental conditions and system states.

Result

More efficient and ergonomic

The feasibility study shows that automation not only increases production speed but also improves ergonomics. As a result, ELNOR benefits from greater efficiency and employees from a less stressful working environment.