Automated point-cloud reconstruction in simulation modeling

Automated point-cloud reconstruction in simulation modeling

Challenge

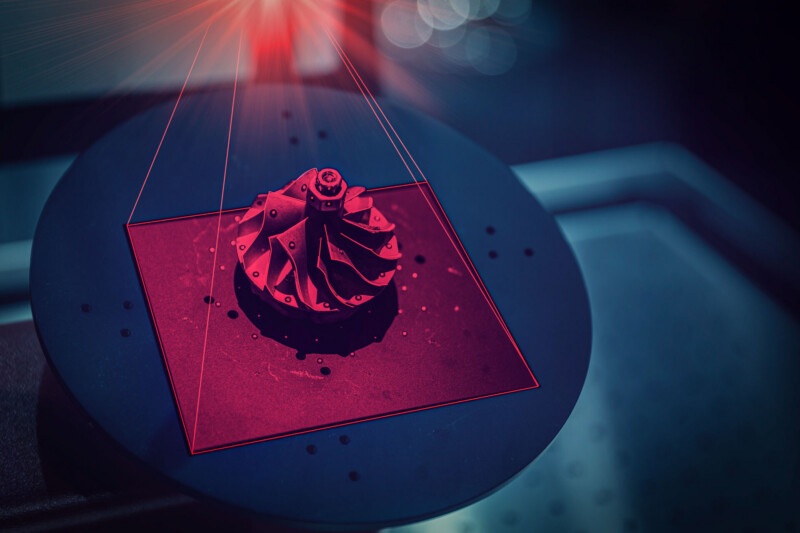

In industrial practice, component performance is still evaluated using idealised scan-to-CAD models, while real manufactured parts contain geometric deviations such as misalignment, undercuts, surface roughness or weld irregularities. These deviations can significantly affect fatigue life and structural performance, yet they are largely ignored or compensated for with conservative safety factors. Although 3D scanning is increasingly available, it is mainly used for dimensional checks. Converting scan data into simulation-ready finite element models remains a manual, time-consuming and expert-driven process, creating a gap between quality control and performance assessment.

Project goal

Via this project (AutoPRISM_IRVA), we enable companies to bridge the gap between as-manufactured reality and simulation-based performance assessment.

The project aims to transition from the idealised scan-to-CAD methods to the more realistic and automated scan-to-FEM workflow. This converts raw 3D point-cloud data directly into analysis-ready finite element models, while retaining critical local geometric features.

It allows engineers to assess fatigue and structural performance based on the real geometry of components, reduce unnecessary conservatism, lower rejection rates and make informed repair or acceptance decisions. By drastically shortening the path from scan to stress analysis,

AutoPRISM supports faster validation, improved design decisions and more cost-effective manufacturing.

Interested?

We are looking for companies to work with us on the valorisation of this project. Interested? Complete the form below and we will contact you as soon as possible.