The big technology leap: Duracell factory in Aarschot made the transition to Industrie 4.0 in five years

The big technology leap: Duracell factory in Aarschot made the transition to Industrie 4.0 in five years

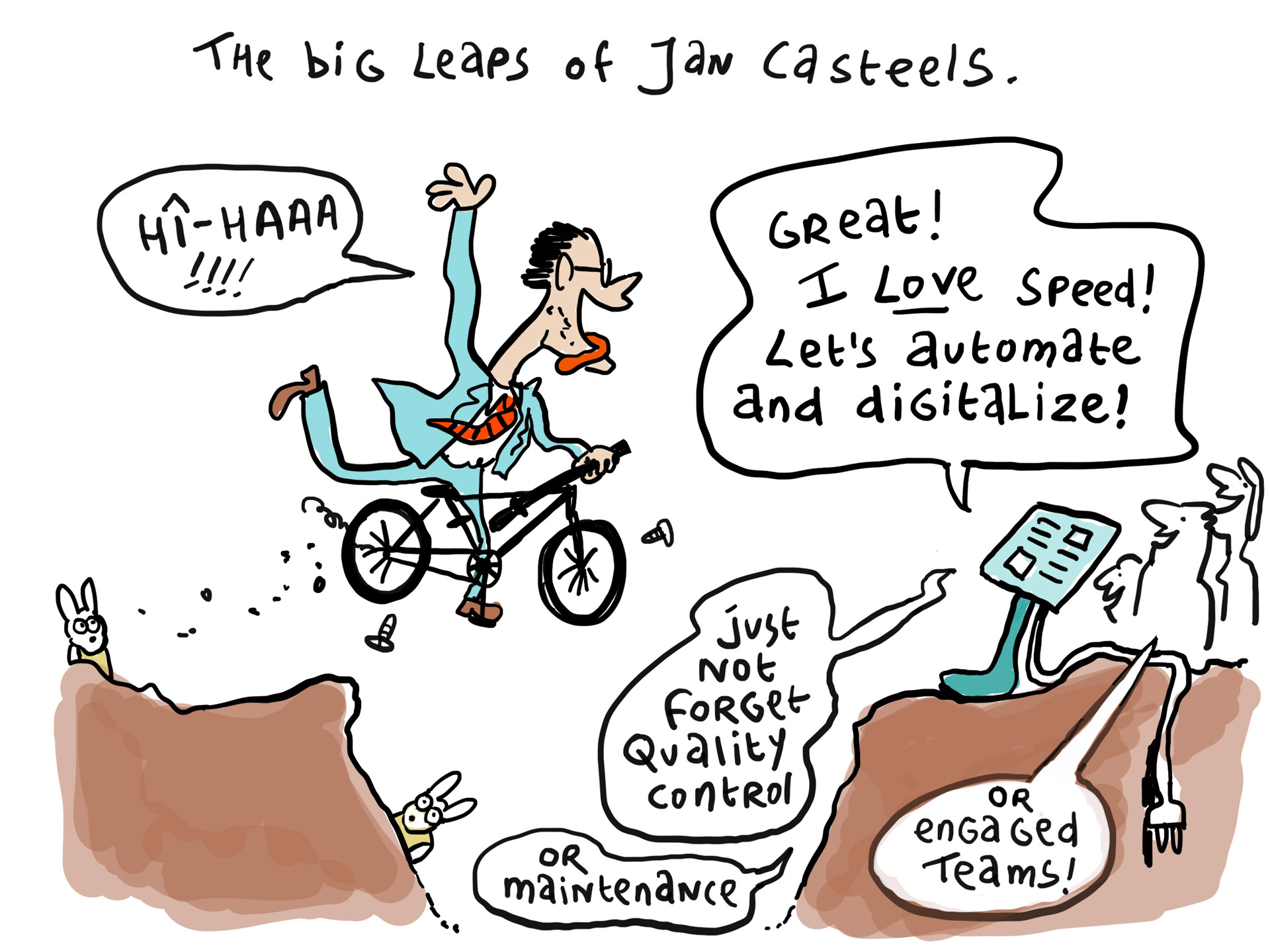

Thanks to a thorough digital transformation, battery production today runs more than smoothly at the Duracell plant in Aarschot. It took about five years to fully embrace Industrie 4.0 and quickly reaped its rewards, making the plant a shining example for other companies. But how do you tackle such a radical change practically? Jan Casteels, vice president of Duracell plants in Belgium, explained at the Flanders Make Symposium.

About 10 years ago, dark clouds were gathering over the Duracell plant in Aarschot. The company had to go through a major restructuring, which involved severe cuts in its product portfolio and the elimination of some 300 jobs. A 75 million investment ended up in the fridge. "We introduced a new shift system to increase our profitability, but that was insufficient to compete with lower wages in other countries," Casteels said. "We had to put our heads together and fundamentally rethink what our 'moat' could be."

A moat, in the economic field, refers to a competitive advantage. Just as in the Middle Ages a moat around a castle could keep enemies at bay, a moat now protects a company from competing companies. The concept was pioneered by renowned US super investor Warren Buffett. "By the way, Buffett is the founder of the Berkshire Hathaway group, of which Duracell has been an independent subsidiary since 2016."

So what specifically would this defence technique consist of? "Pure cost-cutting measures would clearly not suffice, we also needed to increase our capacity, by increasing our production speed," Casteels told us. "We could only achieve that by embracing digitalisation and automation. With automation, the focus was on low-value-added activities."

AGVs as gamechangers

One of the production bottlenecks they tackled in Aarschot was that of manual cleaning of battery cells. Traditionally, each cell was manually rubbed clean with a cloth by a worker after production. "A slow process and also not a quality job for our colleagues," says Casteels. Casteels' team looked at several alternatives, such as cleaning methods using steam and CO2. However, the solution lay in a collaboration with a small company in Hasselt. Together, they developed an innovative laser cleaning technique. "This is not only a faster method, but also an environmentally friendly process," he says.

A larger-scale innovation involved the use of automated guided vehicles, or AGVs. Again, the focus was on tackling low-value-added activities, especially the simplest forklift movements from point A to point B. "This is certainly not an obvious step, but we have learnt a lot over the years about integrating AGVs into our warehouses. This automation was a real game changer in making our logistics operations at the Duracell site in Heist-op-den-Berg more efficient."

Higher reliability through cameras

As production moved into high gear, it soon became apparent that those responsible for quality monitoring could not keep up with that increased pace. In one day, up to 6 million batteries could now be produced at the factory. To assist the quality department, several camera systems were installed, capable of monitoring 15 quality parameters. Instead of random checks, all batteries can now be thoroughly examined, which obviously only enhances the reliability of the sold products.

"This system was also set up with a Hasselt-based company, just like our innovative laser cleaning technology," Casteels stressed. "It clearly shows that you don't always have to look for partners on the other side of the world. Here in Flanders, we have a particularly high level of expertise."

Data analysts for imoroved maintenance

More recently, the Aarschot plant is also focusing on predictive maintenance, with the aim of ensuring that all machines in the company keep running smoothly at all times, with a minimum of maintenance work. With predictive maintenance, the use of data and artificial intelligence (AI) allows you to take the necessary measures at the appropriate time, just before problems threaten to occur.

"This field is not yet mature, but we strongly believe in it. That is why we are attracting more and more data analysts and gradually reducing our number of maintenance technicians. It's a leap of faith, but with full confidence that we'll do well. Over time, thanks to our investments in AI and automation skills, we will improve our maintenance and thus increase our capacity."

Although Duracell is not mentioned in the same breath as technology companies like the Tesla's of this world, the company does have a strong focus on fundamental research. "In 2016, we set a goal to participate in at least one fundamental research project per year and we have succeeded in this so far," Casteels said. "We are collaborating with KU Leuven for several projects and this year we started a new initiative together with VLAIO and Sirris. We want to use AI to automatically adapt to any contextual disruptions to our production processes."

Fast information transfer in team rooms

Human intelligence does remain more central to Duracell's technology journey than ever before. "We are placing much more emphasis on insights into people management. As author John Maxwell succinctly summed it up: 'Everything starts with leadership'," Casteels stated. "We aim for a very close connection between our leaders and their teams, through constant communication. This is how we aim to effectively inform people, motivate them and celebrate their achievements."

The flagships of this human approach are the 'team rooms'. "Small oases of peace on the production floors, with well-insulated windows, air conditioning, lockers and information screens. There, people meet at the relief of shift and can very easily get an overview of everything that happened during the previous shift and what they should best focus on during the next shift. That enables quick information transfer and decision-making."

Duracell introduced these rooms based on the results of an annual engagement survey. "By responding concretely to their feedback, we have further strengthened our employees' engagement. That's how you make sure your people are fully prepared to take the necessary technology leaps."

This presentation was part of Flanders Make's Symposium, the annual event where (inter)national speakers present the technology trends that will shape the future of the industry. The 2022 edition was all about the path to 'a sustainable, digital and competitive industry'.