Data driven process optimization: combining expert knowledge and machine learning.

Deadline

Challenge

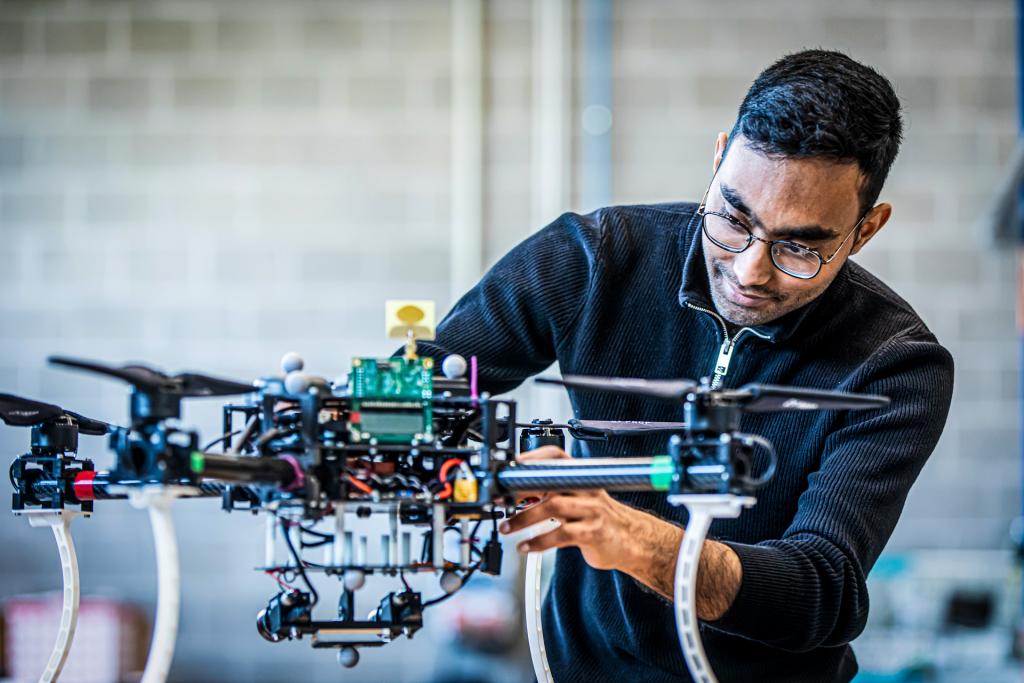

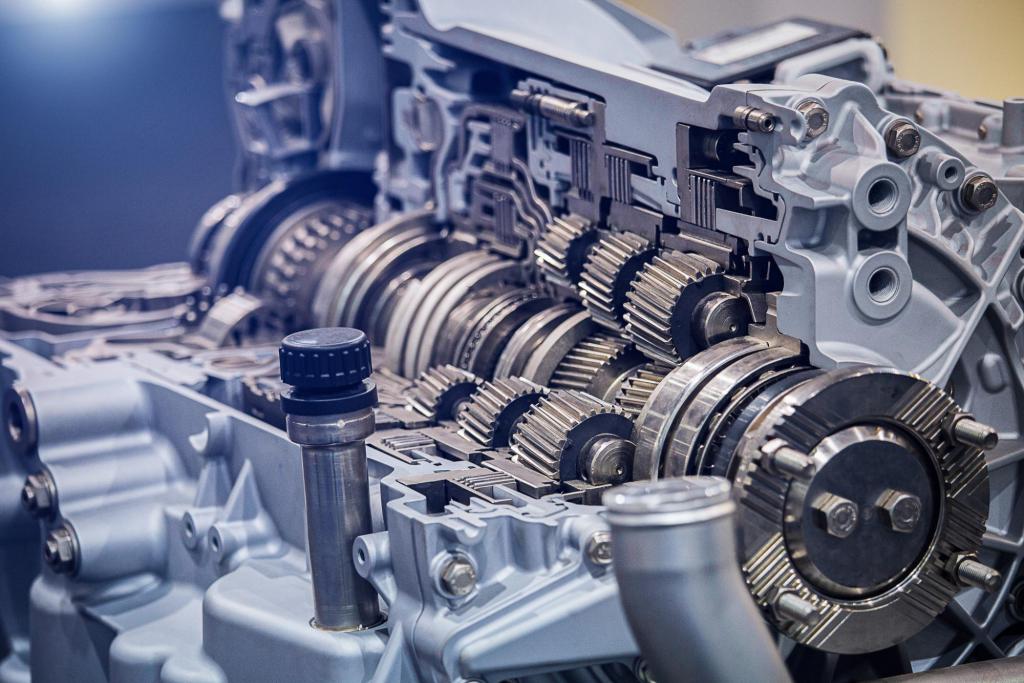

Manufacturing processes, like injection molding or robomolding, rely on specific parameter settings (like thickness, final product dimensions, etc.) that greatly impact the final product quality.

Companies operating these machines aim to optimize these settings to achieve a particular goal, such as minimizing production costs while ensuring the product meets specifications. However, finding these optimal settings is challenging due to the randomness in performance outcomes and the expensive nature of experiments, both in terms of time and cost.

The process optimization problem is inherently stochastic and constrained, often relying on expert knowledge or manual optimization. In this project, we are exploring innovative techniques, incorporating statistical learning methods, to enhance and potentially automate the experiment design. If your company is interested in advancing process optimization, then please get in touch.

Project goal

In this project, we aim to create Bayesian optimization techniques tailored for optimizing manufacturing processes. These algorithms have the potential to significantly reduce time compared to current methods, as they are data-efficient and require fewer experiments. Additionally, they hold promise for automating parts of the optimization process.

Interested to participate in this project?

PROCOPT_SBO is a Strategic Basic Research (SBO) project. We are looking for companies to join the User Group and work with us on the valorisation of the project.

Interested? Complete the form below and we will contact you as soon as possible.