Powering the future with battery energy storage systems

There is a lot of research into how we can further improve battery technologies, as Battery Energy Storage Systems (BESS) are critical to clean energy transition to a carbon-neutral global economy. The ability to store energy from renewable sources for later use or for transport is an important part of the decarbonisation of various industries. Flanders Make is actively involved in a lot of research in the field of battery technologies and companies can also benefit from participating.

Among the various types of BESS, the lithium-ion battery technology is the most widely used type of rechargeable energy storage system. Since the first commercialisation of the Li-ion battery in 1991, this technology has rapidly gained consumer acceptance due to a number of interesting characteristics compared to any other rechargeable battery, such as high energy and high power density, long life and more flexibility in charging and discharging than similar battery chemistries. Today, Li-ion batteries can be found everywhere, from small-sized batteries in portable electronic devices, such as mobile phones, laptops, and tablets, to very large-scale batteries in cars, homes or even industrial sized storage systems.

Industrial applications of batteries

Large-scale battery storage is increasingly used in industrial applications. They are proving their worth in three main categories, and Flanders Make has ongoing research in all of them.

E-mobility

Climate change, air pollution and a shortage of fossil fuel resources are the global challenges driving the regulation for the mobility sector, pushing it towards carbon-neutral drivetrains. Electric driving is on the rise, and the battery as the core component of the electrified drivetrain allows us to move away from CO2-emitting fossil fuels. That same trend is now making its way into large-scale road transport, as well as the maritime and aviation sectors. As the transport sector is one of the most significant sources of air pollution, its decarbonisation is an important step towards a cleaner, healthier and more affordable future for everyone.

Electricity sector

Battery Energy Storage Systems are becoming a key element in the transition of the electricity generation from dispatchable energy sources such as coal and gas to renewable sources such as solar and wind. As renewable energy sources are weather-dependent and intermittent, BESS can effectively store this energy for later use to balance supply and demand, to provide reliable and stable power. The size of these battery systems for grid services can vary significantly from small home batteries for rooftop solar panels to very large battery systems in the order of a few MWh connected to the transmission grid. These large batteries could play a variety of roles in the electricity sector, including frequency regulation, load levelling, backup power, voltage support and energy management.

Manufacturing industry

With regards to the energy efficiency as a core element of Industry 4.0, all industries are trying to find ways to improve their efficiency without causing further damage to the planet. Similar to the electric vehicles mentioned above, forklift trucks, cranes, robots, drones and off-road machines are increasingly being electrified to further reduce the carbon footprint. In addition, batteries play a central role in Industry 4.0, where everything will to be interconnected. The development of the Internet of Things means that many mobile devices and resources need some kind of power source, which is often a battery.

Battery research at Flanders Make

Flanders Make as a strategic research centre for the manufacturing and automotive industry, is at the forefront of electrification of the future vehicles, machines and factories, contributing to a carbon-neutral and sustainable future. In this context, Flanders Make has built up extensive experience in the battery related activities at a system level such as battery architecture and system engineering, electrical and mechanical design, battery management systems and state estimation, advanced cooling and thermal management, functional safety and digitalisation of the battery systems. All these activities are strongly supported by an extensive battery cell, module and pack testing infrastructure, environmental and climatic testing chambers, testing infrastructure for electrical drivetrains and machines, and a modular and flexible high voltage DC simulation system.

International cooperation in the field of research and innovation has always been of great importance to Flanders Make. Given the strategic role of batteries in the EU plans for a clean and digital energy transition, Flanders Make has been actively contributing to innovative battery research at the European level.

A summary on the on-going and upcoming battery-related EU research at Flanders Make is given below and is regularly updated. If any of these projects is relevant for your company, don't hesitate to get in touch.

Electric vehicle battery system for increased range, safety and lifetime

Focusing on battery systems in electric vehicle applications, 16 partners from various EU countries are cooperating together in the LIBERTY project upgrade the performance, safety and lifetime of the batteries from a lifecycle and sustainability point of view. This should accelerate the mass market take-up of battery electric vehicles.

Within this project, Flanders Make is mainly responsible for the performance testing, the validation of the battery system, performing functional safety analysis and contributing to the battery system design. This last part includes a total cost of ownership evaluation during the design phase.

For more information on this project: https://libertyproject.eu/

Integrated sensors for battery cells

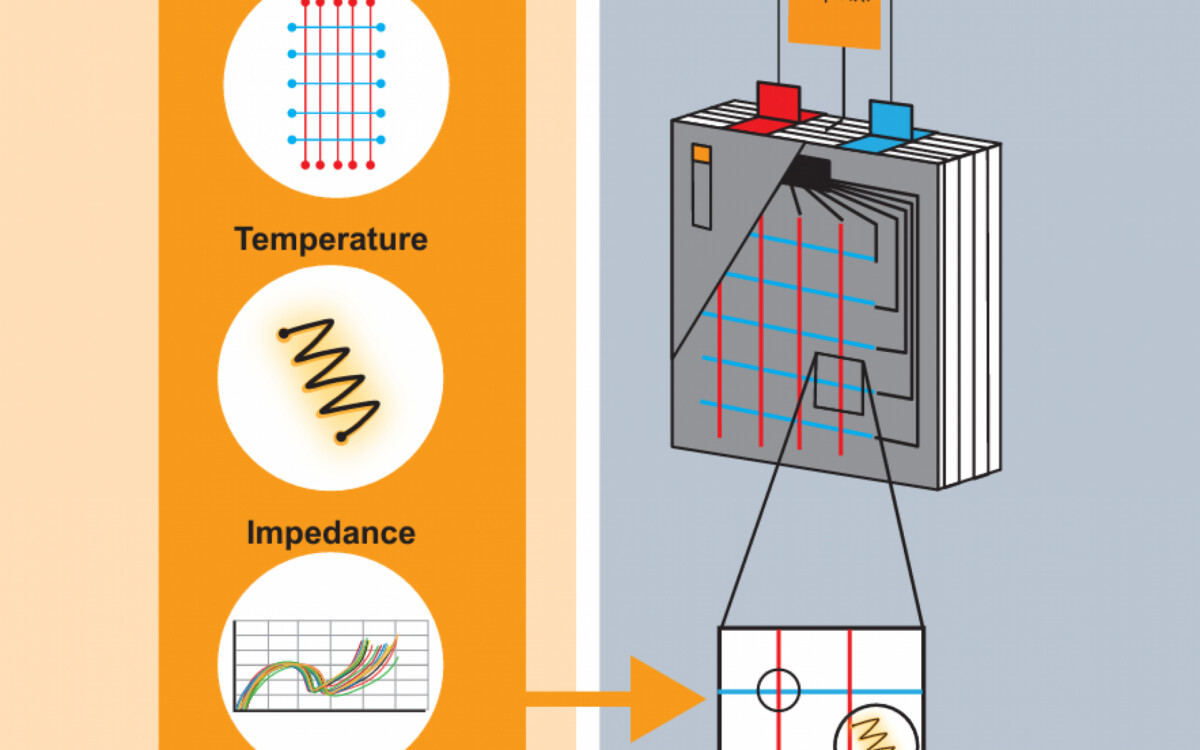

The overall objective of the SENSIBAT project is the development of sensing technologies that will measure the temperature, pressure, conductivity and impedance of Li-ion battery cells in real time. The data and insights generated by these new sensing technologies will be used to develop better Battery Management Systems (BMS) that can improve the safety, reliability and performance of Li-ion batteries for various applications.

Flanders Make will design and build battery modules, and develop advanced state of charge (SOC) and state of health (SOH) algorithms for innovative battery cells with integrated sensors. In addition, battery cell and module testing is another main activity of Flanders Make in this project.

For more information on this project: https://sensibat-project.eu/

Large battery systems for waterborne transport

While the volume and the weight of the battery systems in waterborne transport are less important than in road transport, the high cost of the batteries, especially at system level, and safety concerns are the main barriers to deploying large batteries in marine applications. The SEABAT consortium, consisting of various research organisations and industrial partners from battery manufacturers to shipbuilders, is carrying out state-of-the-art research to address the cost and safety challenges of the large battery systems and enhance the competitiveness of European industry in the marine battery market.

In addition to the technical coordination of the overall project, Flanders Make is leading the research activities for the architectural concept analysis and detailing of a modular battery system. The design of the modular battery system aims to reduce component costs, so that unique ship designs can benefit from economies of scale by using standardised and low-cost modular components.

For more information on this project: https://seabat-h2020.eu/

As part of this research project, we developed a user-friendly battery sizing tool. More about this in our blogpost "Searching for the best electrification solution for your product?"

Vessel battery charging system

As the capacity and range of electric vessels increases, the provision of high charging power is often hampered by the lack of availability of high power fast charging and adequate electrical supply infrastructure in ports. In addition, the lack of standardisation of the vessel charging systems further hampers the deployment of electric vessels of all types. The HYPOBATT project has brought together 18 partners to develop and demonstrate a fast charging system for ships at selected locations. This fast charging station will improve energy efficiency, charger availability and battery life, as well as standardise the fast charging system and develop new business models to make electric ferry operations more sustainable at in the future.

Flanders Make is contributing to this project by carrying out research activities to develop a digital twin of the whole system including the charging device and the battery system, to develop the charger architecture from thermal point of view, and to analyse the influence of renewable energy technologies on the electrical energy flow and the electricity price based on the future electrical infrastructure available in the ports.

For more information on this project: https://www.hypobatt.eu/

Innovative energy storage systems for vessels

Electrical energy storage in most waterborne applications is based on traditional battery technologies. However, specific operational requirements, especially in adverse conditions outside sheltered waters or going upstream on rivers, remain a concern as conventional Li-ion batteries are not able to meet these demanding and flexible requirements. The AENEAS research project, coordinated by Flanders Make, will provide solutions to improve the overall energy efficiency and drastically reduce the emissions of waterborne transport vessels, based on innovative electrical energy storage that is safe and cost-competitive compared to conventional batteries.

In addition to project coordination, Flanders Make contributes to the system modelling and takes the lead in optimising the ship’s power/energy management strategy, conceptual energy storage design at a system level and functional testing of the innovative energy storage systems.

For more information on this project: https://cordis.europa.eu/project/id/101095902

Next generation high-performance and safe-by-design battery systems

The EU project EXTENDED which will be kicked off by mid of 2023, aims to develop innovative battery system technologies that will benefit various transport and mobile applications, by significantly improving performance and safety, as well as environmental sustainability and cost. The developed technologies and solutions will also be optimized for other applications such as stationery batteries. The battery system in EXTENDED will be based on the next generation solid state battery cell technologies. In this project, Flanders Make as the work package leader will be in charge of performance testing and validation of the developed battery systems.

For more information on this project: https://extendedproject.eu/

Digitalization of battery testing from cell to system level

The EU project FASTEST also will be kicked off by mid of 2023. The aim of the second project is to digitise of battery testing, as the existing testing methods, which are mainly based on trial-and-error processes, result in high costs. The digitisation of battery testing will lead to an acceleration of the battery development time, a higher quality of the battery assessment, an improvement of the battery design itself, which will lead to significant cost savings, especially in the development phase. Flanders Make will contribute to the testing of battery cells and modules, the validation of an AI-powered toolchain with regard to the functional failures in the battery system, and also the development of a of hybrid test platform and its digital twin system.

For more information on this project: https://www.linkedin.com/company/fastest-project/

Hybrid Battery Storage Solutions Platform for Multiple Grid Services

Starting in 2024, the Horizon Europe project #HiHELIOS (Demonstrating a high-energy and high-power hybrid battery storage solutions platform for multiple grid services) will pioneer the deployment of 1MWh of hybrid battery storage, carefully distributed across three European countries. It will promote greener and more cost-effective energy alternatives through repurposing second-life batteries. In addition, this project will enhance the field of battery digitalisation: the integration of advanced physics-based models for precise condition monitoring of these second-life batteries will significantly improve their accuracy and reliability.

For more information on this project: https://www.hihelios.eu/

Improved electric ships with DC technology

This European research project focuses on the development of next-generation shipboard energy systems. The project aims to significantly improve the efficiency, safety, and reliability of electrical power systems on board by advancing the use of DC (direct current) technology.

While DC-based primary power systems are increasingly being adopted, secondary systems on most vessels still rely on conventional AC solutions. ALL-DC-SHIPS addresses this gap by developing innovative components such as compact high-power converters and fully solid-state protection systems. These technologies will enable more effective energy management and fault response, while reducing power losses and increasing the overall energy density of shipboard systems.

Flanders Make plays a central role in this project through the design and optimisation of DC power architectures for large vessels. In addition, Flanders Make will develop and construct a secondary DC grid, which will undergo a comprehensive trial period at sea, providing valuable data for real-world validation.

Solutions for electric vessels

The widespread adoption of zero-emission solutions for maritime transport is hindered by several obstacles, including limitations in current battery systems' energy density, safety concerns, the need for durable and sustainable materials, and, finally, economic viability/sustainability.

The European funded project eWAVE brings together 18 leading European partners to mature High-Voltage (HV) and energy efficient technology for electric vessels for future uptake in European shipbuilding sector, using efficient HV modular and scalable battery and distribution systems. It will research, develop and demonstrate solutions for sustainable maritime and inland vessels. This initiative not only aligns with the Horizon Europe programme's objectives, but also contributes to the goal of widespread adoption of sustainable and innovative technologies within the maritime sector.

Fore more information: https://ewave-project.eu/

Optimal battery solutions for heavy-duty applications

To support decarbonization of the heavy-duty transport sector, including maritime transport, battery powered propulsion offers a viable solution. However, these sectors demand a challenging combination of high power for heavy loads with high energy for acceptable distance range between recharges. Battery hybridization is a promising solution as recently demonstrated for the ship application and a go-kart demo.

This project focuses on hybrid battery pack sizing using an optimal combination of current and next generation battery technologies for heavy-duty applications. Additionally, to reduce the operational cost (OPEX) with respect to battery degradation, the project aims to introduce an optionally cloud-connected energy management system (EMS) to further extend application range while optimizing battery lifetime.

Transitioning to a Circular Automotive Industry

With the rapid growth of electrified vehicles and the forecasted surge in used EV batteries, circular design and remanufacturing readiness are becoming crucial. Flanders Make coordinates CYPRESS, a project part of the Interreg Meuse-Rhine (NL-BE-DE) programme and co-financed by the EU. We are driving innovation in battery system design to support a circular and resource-efficient automotive sector. The project supports the transition of automotive SMEs towards circular value chains - from design and assembly to disassembly and reuse - ensuring long-term economic and environmental resilience.

Flanders Make will contribute cutting-edge expertise in:

- Design-for-disassembly to simplify repair, reuse, and recycling

- Remanufacturing strategies to extend battery life and reduce costs

- High-performance battery system design, tested in advanced facilities

Join us in our research

As you can see, a lot of our efforts revolve around innovative battery technologies to facilitate the crucial transition to renewable and carbon neutral energy sources. If you want to be part in our upcoming projects or want us to solve a battery challenge, then feel free to contact us.