Insights

Read more about our pioneering research and its practical application here.

Overview

8 results

- (Article)

From “black box” to co-pilot: Bricsys opts for transparent AI in design software

2 min read

- (Webinar)

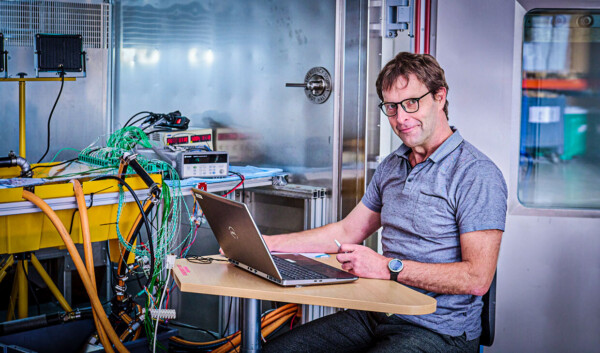

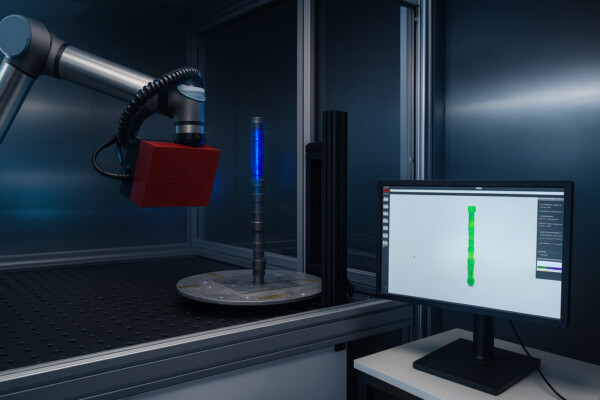

Tech@Lunch January: Advancing gearbox reliability: Vision-assisted condition monitoring

15 Jan 2026•Online

- (Webinar)

Tech@Lunch December: AI security and compliance: what lies ahead and how can we prepare?

12 Dec 2025•Online

- 1

- …