Charge Towards Electric Trucks: The Case of Lambrecht Constructie

The market for electric trucks is poised for significant growth. Although currently modest, advances in battery technology and government incentives for zero-emission vehicles will change the landscape. By 2030, it's predicted that a third of all trucks in Europe, North America and Greater China will be zero-emission vehicles, either battery or fuel cell powered (reference). Companies in the transport industry will need to make key decisions to adapt to this shift in an efficient way.

Flanders Make is constantly working on innovative solutions. For example, the E-trova team collaborated with Flanders Make to develop a method to convert diesel trucks to electric variants within 48 hours , marking a significant step towards sustainable freight transport.

Business Case: Lambrecht Constructie nv

Lambrecht Constructie nv, a family-owned Belgian company known for manufacturing trailers for dry goods such as cattle feed, is preparing to embrace truck electrification. Together with us, they are exploring ways to electrify their feed trailers, which are currently diesel-powered. This transition isn't just about keeping up with industry trends; it's also about reducing CO₂ emissions and noise - factors that are critical in areas with animals.

"Although Lambrecht Trailers is a rather small SME, we are not afraid of innovations. We are convinced that this sets us apart from our foreign competitors. Research institutes such as Flanders Make are very important to us. With their expertise, we can switch faster as we have limited engineering capacity ourselves. In addition, Flanders Make keeps us up to date with the latest technologies applied within our sector ."

Francis Verhelst

CEO, Lambrecht Trailers

Key Challenges

Electrifying a trailer presents a number of challenges. The first is to determine the optimum trailer configuration. This involves different types of actuators - such as hydraulic pistons and Archimedes screws - that can be powered in different ways. In a thermal truck, these will be powered directly from a diesel engine, via a mechanical Power Take Off (PTO) from the truck. In an electric truck, they can be powered via a trailer-mounted battery or electric PTO. Accurate modelling of these configurations is essential to quantify benefits such as reduced CO2 emissions and power consumption.

Another key challenge is the limited range of electric trucks, which can affect the logistics of hauliers using these trailers. To overcome this, tools that simulate power consumption throughout the delivery day are crucial. These tools help decide whether it's more efficient to power the trailer's actuators from the truck's battery, potentially reducing range, or to opt for longer stops at unloading facilities to recharge.

Solution: An innovative tool...

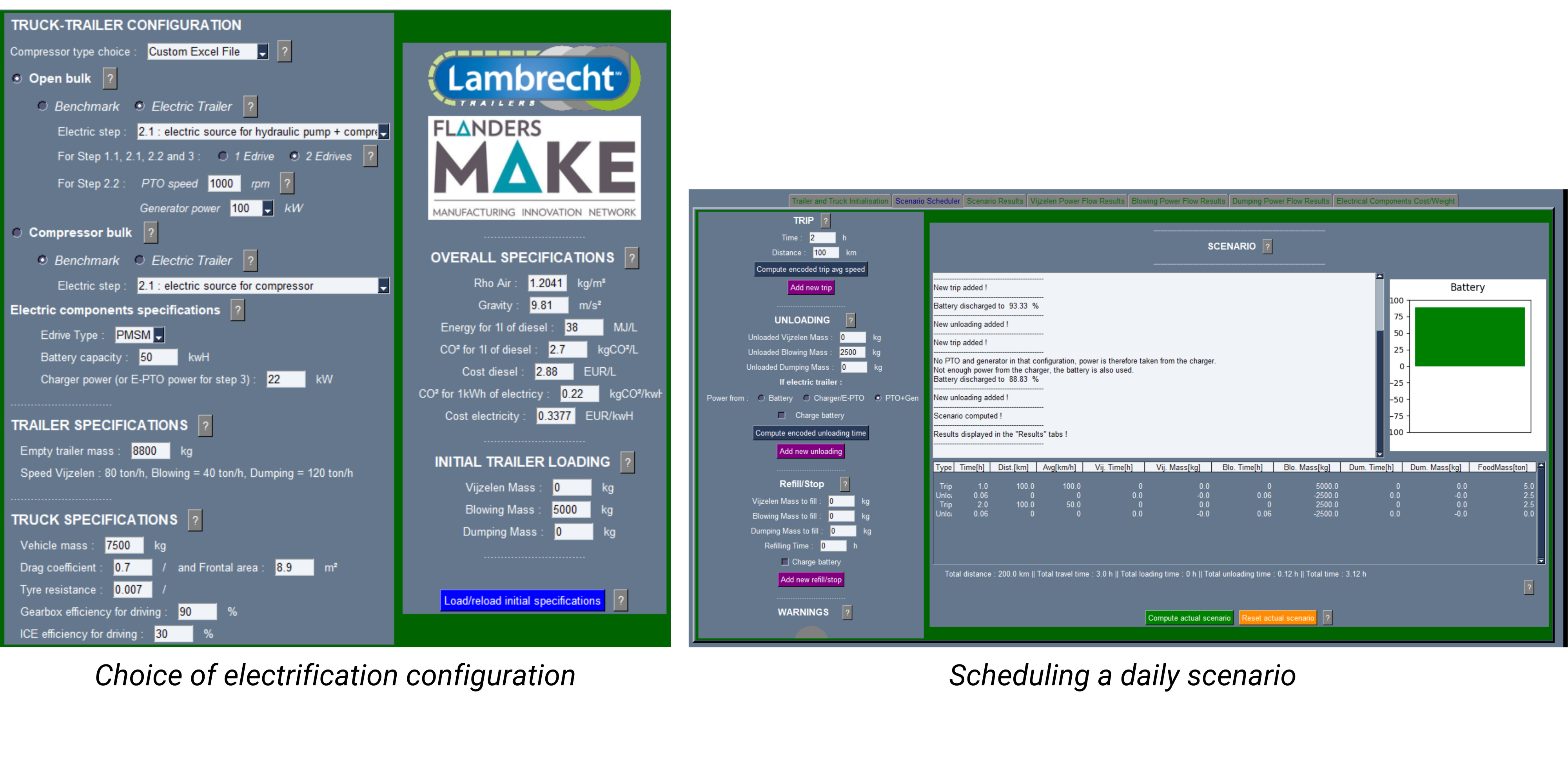

Together, Lambrecht and Flanders Make have developed a versatile tool based on Python models of the electrical and mechanical components. This tool, which uses knowledge from our HyperDrivetrain toolbox, allows users to simulate different trailer architectures and integrate them into a scheduler for delivery day scenarios.

Users can customise features such as battery power, type of electric motor, etc. They then create a scenario based on logistical details such as feed volumes for each customer, delivery distances and power sources:

...for smarter planning

As a result, the user can visualise the overall power flow, power consumption and battery state of charge throughout the day, as well as an indication of the cost/weight/volume of newly added electrical components.

This tool is set to revolutionise Lambrecht's approach to implementing electrification for heavy-duty transport. It helps in navigating the challenges of electrifying the trailers, resulting in optimal and realistic daily delivery schedules for their customers.