Online Portal for Plastics Designers and Manufacturers

Duration: 1/2/2025 - 31/1/2027

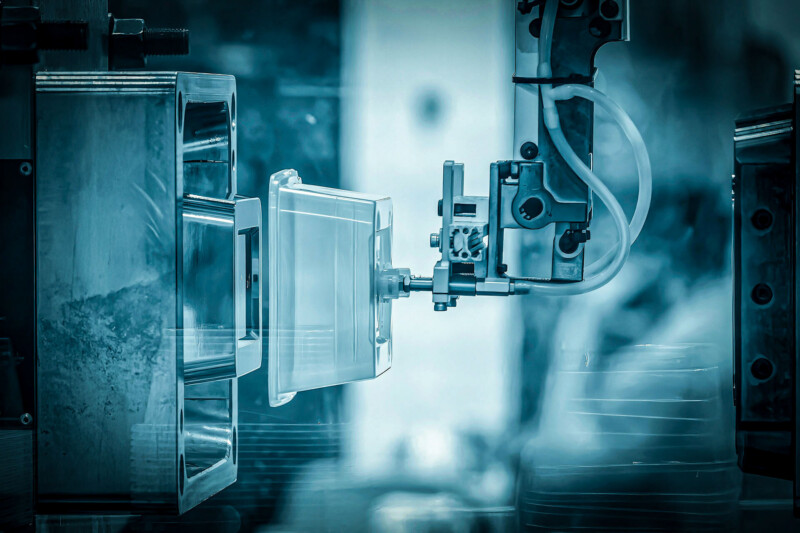

Through this COOCK project, we are streamlining the quotation process between product designers and injection moulding companies.

About OPKOP

The quotation process between product designers and contract injection moulding companies is often time-consuming and requires many iterations.

With the Coock+ OPKOP project, we want to digitise and accelerate this process via a web-based platform that makes it more transparent, efficient and user-friendly.

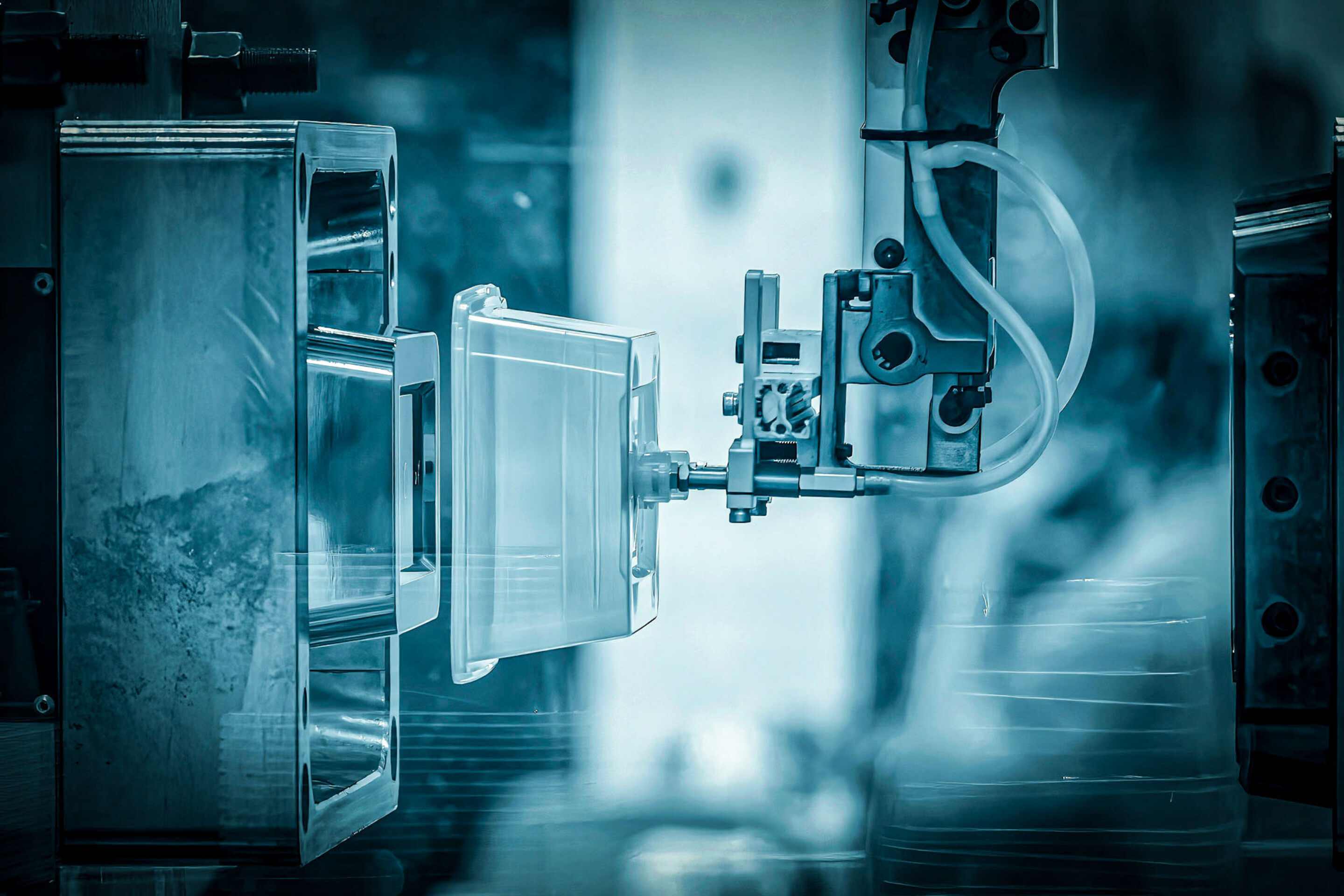

The platform will help designers to:

- substantiate material choices,

- analyse designs for manufacturability, and

- automatically prepare designs for quotations.

Target group and impact

The target group consists of SMEs that design or manufacture plastic products — both designers and contract injection moulding companies — supplemented by IT service providers who support the digitisation process.

- Designers receive faster feedback on manufacturability.

- Injection moulding companies save time and can prepare quotations more quickly, putting them in a stronger position against foreign competitors.

- IT partners help to further develop and implement the platform.

Vision for the future

Although this project focuses on injection moulding as a production process, the ambition is to expand the platform to other production techniques and new functions, such as automatic quotation generation, at a later stage.

This project focuses primarily on design agencies, injection moulders, mould makers, software providers, etc.

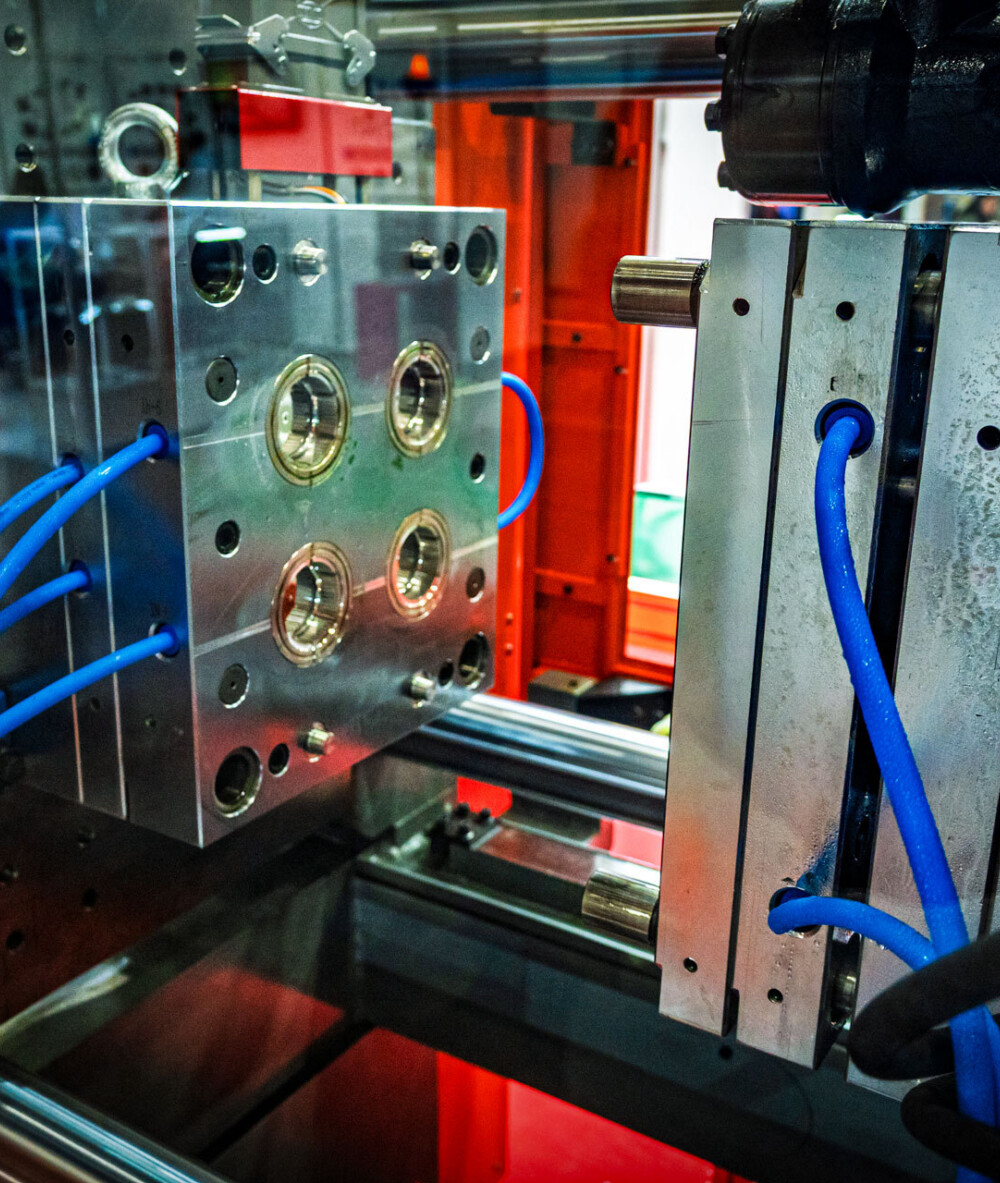

Injection moulders can:

- Embed the portal into their own website;

- Enter their own manufacturability rules based on their own process knowledge and machines;

- Receive substantive guidance when selecting lesser-known or recycled plastics;

- Speed up their quotation process by:

- Providing faster design feedback to designers;

- Receiving designs that can be manufactured on their own machines;

- Immediately seeing which machines are suitable for producing a design;

- Obtaining starting values for preparing quotations.

Designers can:

- Match their designs to the manufacturability and cost of one or more injection moulders and/or machines;

- Receive substantive guidance when selecting lesser-known or recycled plastics;

- Be able to speed up their quotation process by:

- Receiving faster design feedback from injection moulders;

- Integrating design feedback into their design more quickly.

Software-providers can:

Further refine the portal and make it more user-friendly by:

- Developing it further to enable injection moulders and design companies to collaborate with each other;

- Developing it further for the specific requirements of injection moulders and linking it to their quotation software.