Verified novel sealing concept improves oil-jet cooled motors

The development of the next generation of electric vehicles requires drivetrains that are more compact, powerful and robust at the lowest possible cost. These more compact drivetrains operate at the same power levels as their larger equivalent drivetrain. Thus they need to dissipate their heat in a smaller volume. As a result, more advanced liquid cooling methods for drivetrain components are needed to improve the heat dissipation and further increase compactness and power density. In a recent study, we demonstrated the high potential of the direct oil jet cooling approach in a modified industrial motor, with an increase in power density of up to 50% compared to water cooled motors. Now, with a new, verified and patented approach, we have developed a contactless sealing concept that makes this oil-jet cooling method also suitable for high speed operations.

In past oil cooling studies, we determined the benefits (+50% of power density) of this oil jet cooling approach, but several challenges have been identified:

- The oil jets hit the coils in an uncertain manner, e.g., sometimes angled.

- The oil jet situation (e.g. splashing) can change suddenly due to small changes in oil temperature or flow.

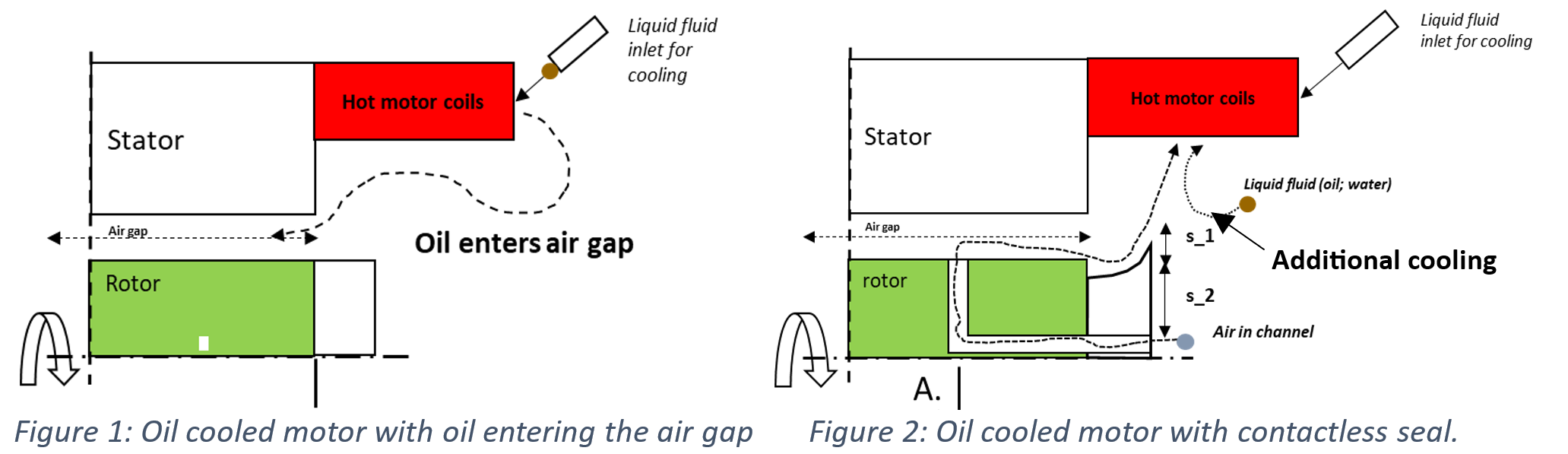

These complex jet flows cause a major problem as oil can creep into the air gap causing high friction losses which increase sharply at higher rotational speeds. This limits the oil jet cooling methods to lower motor speeds, which is counterproductive. Keeping oil out of the air gap would dramatically increase the benefits of oil jet cooling. The accompanying video demonstrates the complex oil jet cooling in a transparent engine version of an industrial prototype.

This is why Flanders Make has developed a contactless hydrodynamic sealing concept which allows the rotor to act as a small centrifugal air pump, keeping oil out of the air gap by creating a reverse air flow. The sealing concept has been industrially verified inside the SingleOilCnL project and the novel approach has been patented.

The main features of the sealing concept are the following:

- Churning losses inside the air gap of oil jet cooled motors are eliminated, regardless of motor speed.

- The sealing concept can even further cool the motor by influencing the oil jet flow via the reverse airflow.

The end result: A direct oil-jet-cooled motor with up to 50% more power density than a water-cooled motor and no churning losses in the air gap, independent of the motor speed.

Dana Inc. has successfully developed a proof-of-concept electric motor using this technology and is currently investigating the potential usage in its next generation electric drive units. Meanwhile, our research continues to advance the next generation of electric vehicles, together with our industry partners. On our annual symposium in 2024, we also plan on showing a demonstrator for this technology.

What do we offer

- Model-based feasibility studies to optimize oil jet cooling & novel patented sealing concepts in your drivetrain

- A robust design methodology to design (CAD) your oil cooling & sealing concepts in drivetrains with verified robustness, no oil-material compatibility issues and no additional churning losses

- Validation testing with our flexible active cooling/lubrication & HiL infrastructure to verify the cooling & sealing performance of your drivetrains