Automatic chamfering and insertion of insulation in electric motor production

Automatic chamfering and insertion of slot insulation in electric motor production

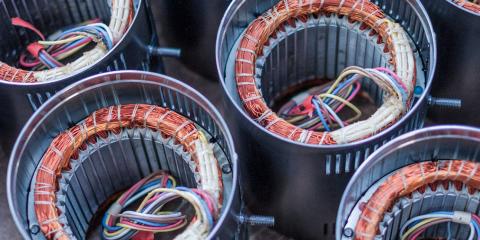

ELNOR Motors, a manufacturer of electric motors, wanted to automate the machining of parts in the production of electric motors. In particular, they wanted to automate the chamfering of the outer edge of the stator and the insertion of insulation into the slots of the stator. These processes were already automated, but the operator had to manually place the stators on the machines, leading to suboptimal use of resources and ergonomic problems.

"A huge help for our operators, who will perform less uncomfortable manual work as a result."

ELNOR MOTORS

What did Flanders Make do for ELNOR MOTORS?

To address this issue, ELNOR conducted a feasibility study together with Flanders Make. The study examined the physical operations in the processes and tested them using a collaborative robot (cobot) and a two-dimensional vision system. Feasibility was proven for several process steps, including detecting the burr side of a stator, identifying damage to a part and ensuring quality control after slot insulation insertion.

Moreover, a test setup showed that the use of 2D vision and a cobot could facilitate the correct placement of motor stators on the slot insulation insertion machine. This implementation reduced the need for manual intervention and improved accuracy.

The feasibility study also looked at the investment perspective, determining the return on investment and analysing factors such as operator involvement and cycle time scaling. A cost model was used to assess the feasibility of the required investment.

Based on the findings of the feasibility study, Flanders Make provided ELNOR with valuable insights to determine the profitability of an automated production process, as well as the extent to which automation should be implemented. The study helped ELNOR assess the impact of automation on process results and added value for the operator.