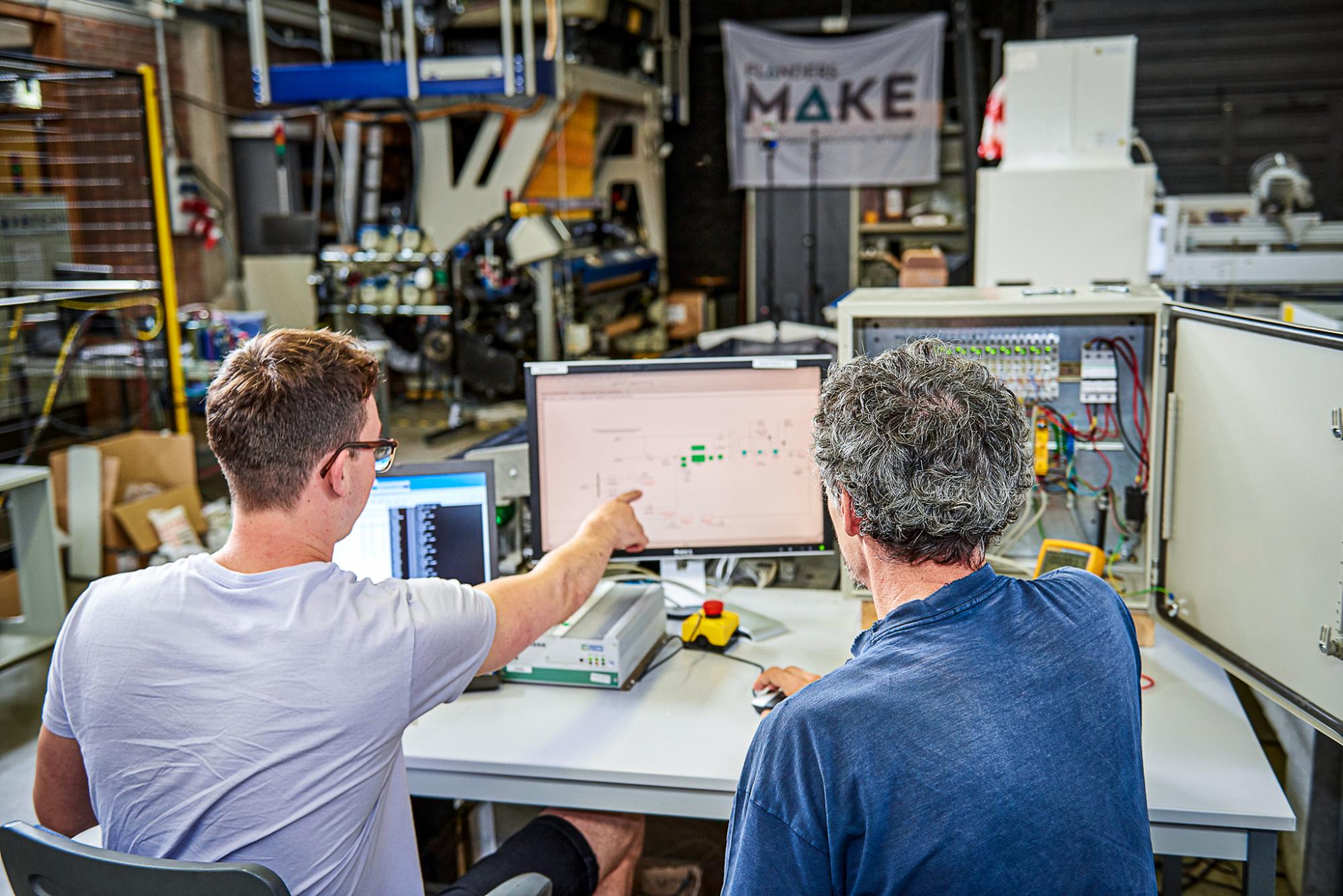

Development of model-based controllers for increased system performance

We support machine builders by using tools to efficiently create better performing controllers for their products. Using our experience in combining theory and application insights, we employ model-based technologies. This allows us to leverage our knowledge about the system dynamics to create real-time, optimally performing controllers.

What do we offer?

In the quest for lighter, faster, stronger or more energy-efficient products, large-scale optimisation problems arise in different product development stages: e.g. modelling, parameter estimation and optimal control.

Companies that manage to solve these problems efficiently gain an important strategic advantage. We help to accelerate the engineering of a working controller prototype, we give advice to achieve state-of-the-art computational efficiency and assist companies in creating a long-lasting, yet flexible control software solution. Our offer consists of:

- modelling and model identification of drivetrain system dynamics;

- controller type selection;

- model-based controller design and tuning;

- development of a learning or adaptive controller if so required by the application;

- development of an optimal controller;

- accelerated controller testing and validation.

Our unique software

We use various unique software toolboxes in this process:

- Linear control toolbox

- Learning control toolbox

- Context estimation and adaptive control toolbox

- Vibration/noise control toolbox

- Nonlinear optimisation and algorithmic differentiation toolbox

- Optimal drivetrain co-design toolbox

- Optimal cam design toolbox

- Dynamic programming toolbox for optimisation, including discrete variables

- Offline and online optimal path planning for AGV’s, drones…

- Controller validation toolbox

Customer Success story

The DUCO energy systems are more efficient thanks to machine learning and advanced control.

Problem

Duco contacted us to investigate to what extent their DucoBox Eco could respond better to the comfort wishes of owners and the varying climate conditions in their homes.

Solution

We used our expertise to implement an advanced control strategy. This new algorithm uses models of the Duco systems, the residents and the house. In this way, we predict the impact of the various control actions on comfort, cost and energy consumption. Expertise in the field of machine learning was also applied to analyse the impact of the residents' energy consumption.

Customer value

Thanks to this study, Duco can determine how much energy and costs a family can save by installing the DucoBox Eco ventilation heat pump in an All-Electric or Hybrid setup. Corresponding analyses and the new control techniques will also be applied in future Duco systems.