Cobots and workplace safety: it's more than technology. Do the test here!

Cobots on the verge of Industry 5.0

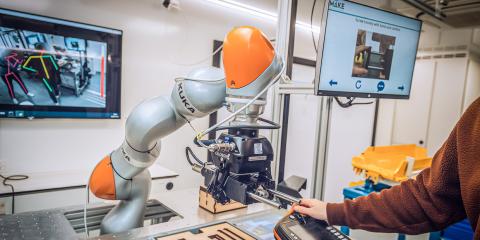

Collaborative robots, or cobots, are designed to collaborate with humans in a shared workspace. We define a cobot as "any type of robot used in an industrial and/or logistical context, operating with a human co-worker in a shared work environment". Unlike industrial robots, collaborative robots (cobots) work without safety fences. This changed context leads to the need to approach cobot safety system wide. Yet the current safety focus of collaborative workspaces is primarily on technology design. Technology was central to Industry 4.0, but in the upcoming Industry 5.0 the focus lays on human-centricity. That is why cobots will have an important role in Industry 5.0.

Undisputed potential but lagging adoption on the work floor.

It should come as no surprise that robotics are on the rise to support human labour. Labour shortages and productivity optimization are stimulating organizations to deploy more robots and cobots.

The potential of cobots is beyond dispute. They can perform tasks that are repetitive, strenuous, or dangerous. As a result, humans can focus on more complex or creative work. The installation of cobots grew by 50% between 2020 and 2021. Still, cobots represent only 7.5% of the total robot installations worldwide. However, they are clearly gaining popularity.

The cobot safety contradiction

Cobots are engineered to operate safely around humans. They are equipped with built-in safety features such as sensors and cameras, that allow them to detect when a human is nearby. Cobots can also adjust their speed and movement to avoid collisions. This is why some label cobots as "inherently safe".

Yet, the notion that cobots are "inherently safe", can create a deceptive feeling of safety. This notion takes a machine safety focus. It is blind to the fact that there may also be risk factors other than machine safety, like stress caused by the cobot or a lack of training. When machine safety is the focus, cobots can be too safe. Meaning that cobots will be so safe that they hinder productivity as a result of the strict application of regulations. For instance, a cobot that stops mid-operation due to a restriction in its power threshold. This cobot safety contradiction leads to confusion for the user.

In addition, there is also lack of knowledge about the safe operation of cobots. All these elements contribute to the low adoption rate of cobots.

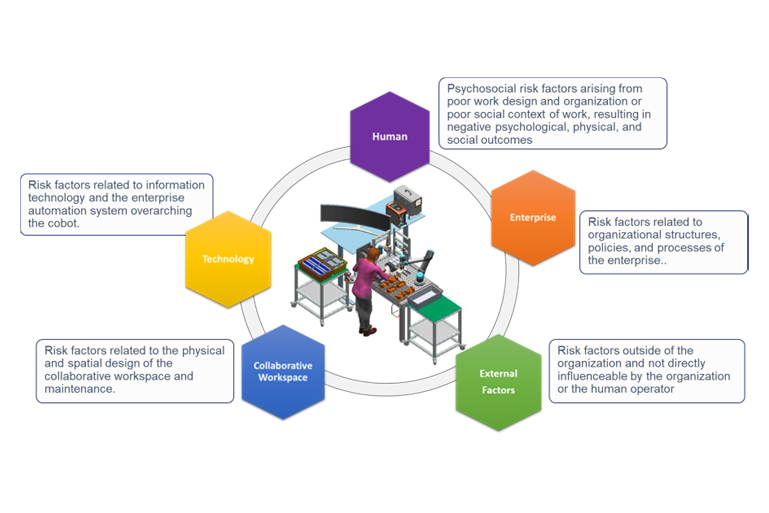

To avoid confusion, cobot safety needs to be approached from a system-wide perspective. It is necessary to take both the technical design and the well-being of operators into account.

Tool to increase system-wide safety awareness and knowledge

To address this issue, we created the Cobot Safety Readiness Assessment Tool. This diagnostic, self-assessment tool helps companies to assess their cobot safety readiness. The tool also increases awareness and knowledge about system-wide cobot risk factors.

HOW ‘SAFETY-READY’ ARE YOU FOR COLLABORATIVE ROBOTS? DO THE TEST!

To test how ‘Safety-Ready’ you are to install a cobot, we have developed our Cobot Safety Readiness Assessment Tool. The tool is a preparatory, informative instrument and does not replace the mandatory safety risk assessment. All involved stakeholders can use the tool which results in more safety reflection and supports better decision-making.

Sources and more information

- Berx, N., Adriaensen, A., et al. (2022) ‘Assessing System-Wide Safety Readiness for Successful Human–Robot Collaboration Adoption’, Safety, 8(3), p. 48. doi: 10.3390/safety8030048.

- Berx, N., Decré, W., et al. (2022) ‘Identification and classification of risk factors for human-robot collaboration from a system-wide perspective’, Computers & Industrial Engineering, 163, p. 107827. doi: 10.1016/j.cie.2021.107827.

- Berx, N., Decré, W. and Pintelon, L. (2022) ‘Het veiligheids spanningsveld bij slimme cobots’, in Dhondt, S. and Dessers, E. (eds) Robot zoekt collega. Kritak. Available at: https://www.lannoo.be/nl/robot-zoekt-collega.

- Cotta, J. et al. (2021) Industry 5.0 Towards a sustainable, human-centric and resilient European industry. Brussels: European Commision. doi: 10.2777/308407.

- International Federation of Robotics (2022) World Robotics 2022, Market Presentation. https://ifr.org/downloads/press2018/2022_WR_extended_version.pdf