Infrastructure for electromechanical drivetrain testing

We offer our electro-mechanical test rigs to test drives and transmissions on component level.

Location: FlandersMake@.UGent

Electromechanical component test rig

With our flexible electromechanical component test rigs, we provide services and access to our test infrastructure for components such as electric machines, transmissions and power electronics in realistic test conditions. Due to the extensively available power sources, cooling methods, sensors and load emulators, the setup can handle many combinations of said components. Our high-power ITHACA test bench is temperature controlled (calorimeter) and goes up to 150 kW and very low speeds. For lower powers, we can test even down to 1 Nm (e.g. stepper motors). We can test on:

- Efficiency;

- Machine level control;

- Condition monitoring/control and dynamics of drives (DOL or with frequency converter);

- Belt transmissions and gearboxes (straight and in-line);

- and (in-situ) magnetic material characterization.

Hardware-in-the-loop (HiL) allows to emulate your application (already available: wind, wave, ICE). If required, we can adapt or design a test setup to your needs.

Technical specifications

- Power: up to 150 kW continuous

- from standstill up to 6000 rpm,

- High torque up to 45 kNm, 60 rpm

- Temperature controlled incl. calorimeter (150x80x100cm)

- High speed: up to 22 kW & 15.000 rpm and up to 75 kW & 9500 rpm

- Low power machines down to 1 Nm (stepper motors, BLDC machines)

- Supply:

- Grid supply: 3x230 VAC and 3x400 VAC (max. 400 A)

- Variable programmable AC current source: 3x0-465 V / 180 kVA

- 4 quadrant variable DC current source: 30-800 VDC / 240 kW / 400 A

- Different cooling methods: water-glycol (-20°C to 80°C), oil, air

- High-end flow sensors, temperature sensors

- Testing at higher temperatures

- The lab is equipped with the latest and most precise power analyzers, torque transducers and other secondary equipment.

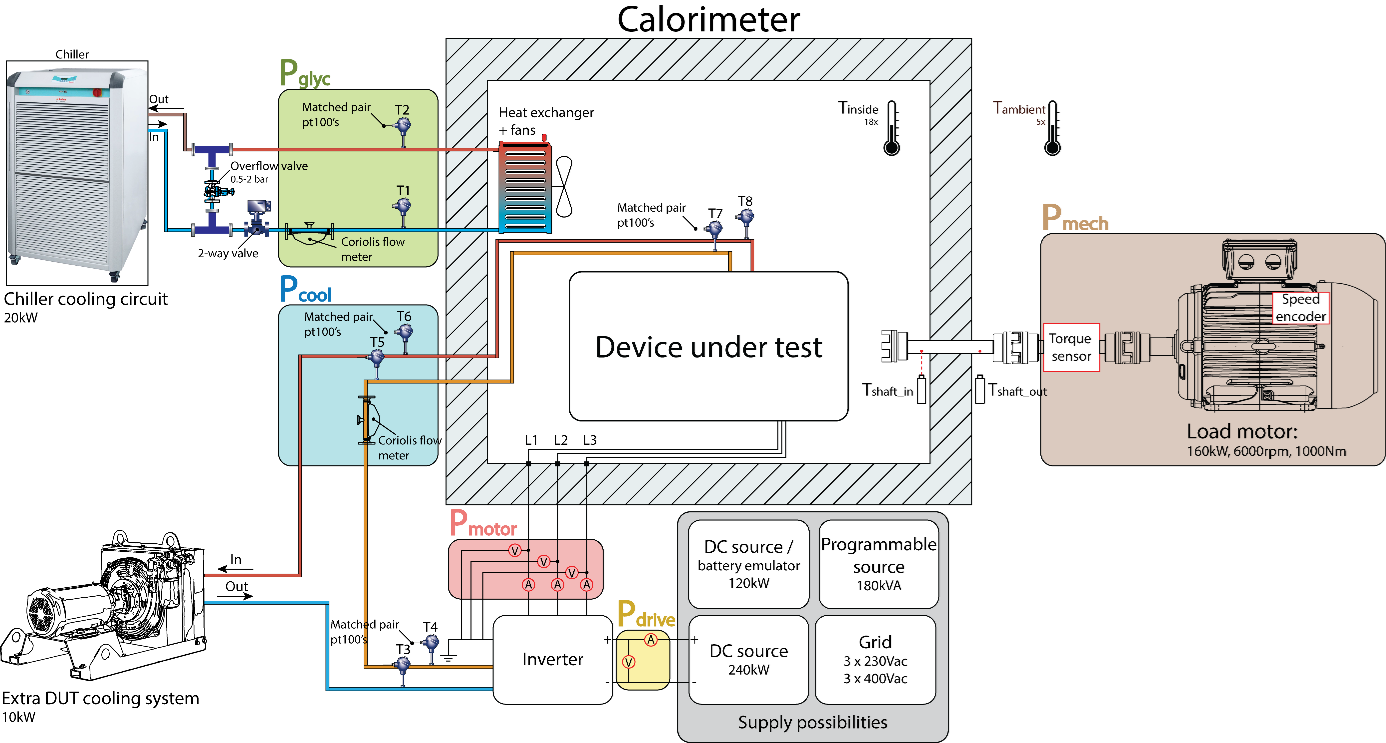

Advanced thermal characterization and validation of drivetrain components & systems

In the large dedicated calorimeter (see figure) you can measure power losses with very high accuracy (< 1%) and even determine overall efficiency for repetitive dynamic motion profiles, which allows to build up and/or validate detailed power loss models for drivetrain components and systems. With the high-speed thermal camera (also available for rental) you can identify fast rotating hotspots, analyze thermal component interaction, cross-check calculated system temperature distributions and validate IR sensors.

Technical specifications

- Specifically designed for drivetrain testing

- DUT max test sizes: 1,3m x 1,0m x 1,8m

- Programmable bi-directional DC power source 120 kW for battery load emulation

- Load motor 150 kW, 6.000 rpm max, 1.000 Nm for ICE, wind, driving cycle emulation,…

- Variable AC power source 400 V / 180 kW

- Variable DC power source 800 V / 180 kW

- DUT power loss measurement up to 20 kW with accuracy of <1%

- Various DUT cooling methods: water-glycol -20°C up to 80°C, oil, air

- Elevated temperature testing possible

- High-end high-speed thermal camera with framerate 233 Hz, -40°C up to 1200°C

HiL test rig for wind turbine emulation

Our dedicated hardware-in-the-loop (HIL) test rig for wind turbine emulation allows you to efficiently develop and test your newly developed control strategies for a wide variety of emulated operating conditions in a safely controlled environment, which enables you to reduce the cost of development and testing. The control strategies under test could be classical control methods (that are often based on explainable physical laws) as well as AI (i.e. more data-driven machine learning) techniques, for example: torque control, (switching) Model-Predictive Control (MPC), Reinforcement Learning (RL) and specific control methods related to wind applications such as Maximum Power Point Tracking (MPPT).

The test rig consists of a 11 kW driving motor that is connected to a 10 kW axial flux permanent magnet generator. The driving motor is controlled by an industrial Danfoss drive, whereas the control of the generator is highly configurable using the dSPACE MicroLabBox Real-Time Interface (RTI) for simultaneous generator control and sensor data-acquisition. Moreover, a flywheel (70cm) has been installed to emulate inertia effects, as well as a 4:1 planetary gearbox and high-accuracy torque sensor. Currents, voltages and shaft speed are monitored using the appropriate sensors for adequate characterization and validation of the performance and efficiency of your tested strategy.

Technical specifications

- Driving motor: induction motor 11 kW, 6-pole, 400/690V, IE3

- Danfoss drive 15 kW IP21 (control of driving motor)

- Flywheel: 70 cm diameter, 5 cm thickness

- Generator: 10kW, 260rpm axial permanent magnet generator

- Planetary gearbox (TANDLER ServoFoxx PL2 B1), ratio 4:1, rated torque 840 Nm, max torque 1350 Nm

- dSPACE MicroLabBox: Data-acquisition of sensor signals + control of generator

- Sensors

- Torque sensor: DR-2112/M450 (Lorenz Messtechnik), 500 Nm, accuracy 0.1%f.s.

- Absolute encoder AFM60B-BDTA008192 (SICK), gray code, 8192 max steps per revolution, 4096 max number of revolutions

- 3-phase LEM current sensors

- Voltage sensors

What do we offer?

Electromechanical component test rig

We offer services on the test rig for the testing of drives and transmissions on component level.

Advanced thermal characterization and validation of drivetrain systems & components

We offer services on the test rig to build up and/or validate detailed power loss models for drivetrain components and systems.

HiL test rig for wind turbine emulation

We offer services on:

- A HIL platform to safely develop or test your new AI or classical control strategies for wide operating ranges: MPPT strategies, torque control, switching MPC, optimal torque methods, residual reinforcement learning…;

- Fully instrumented/sensorized HIL setup that allows you to adequately characterize and validate the performance and energy efficiency of your tested strategy;

- Opportunity for knowledge transfer and collaboration based on our expertise and control methods/toolboxes applied on your specific case.