Monitoring and characterisation of wear-induced material degradation

We can detect, characterise and analyse wear patterns on metal surfaces to assess the remaining lifetime of crucial machine components and reduce maintenance.

What do we offer?

Tribological phenomena (friction, lubrication and wear) have an important impact on the remaining useful lifetime (RUL) of crucial machine components like bearings, cam rollers or gears. By combining our state-of-the-art test infrastructure with computational tools as well as our expertise, we provide both experimental and computational support extending your maintenance intervals and reducing the corresponding costs.

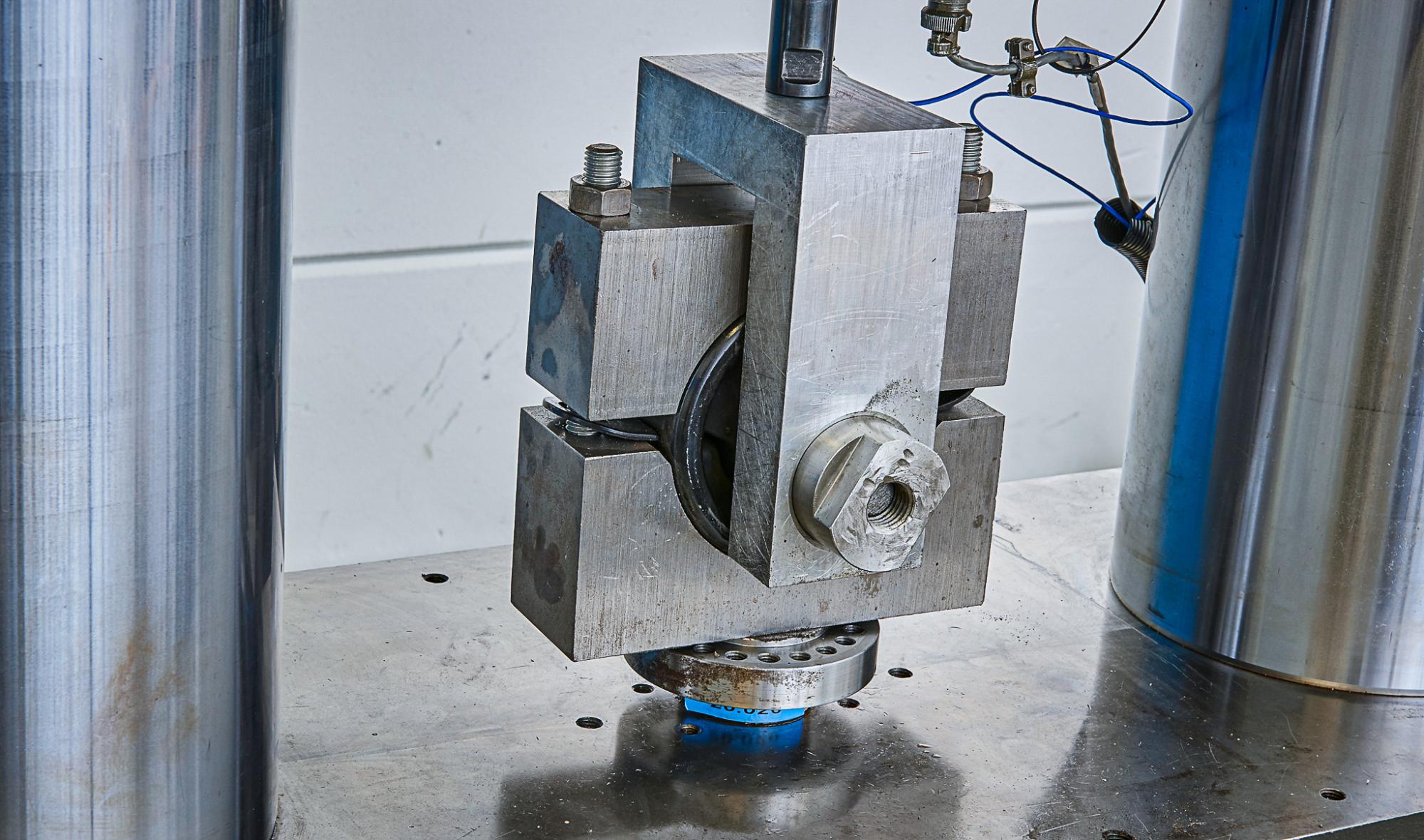

- Experimental support: We test the tribological response of materials (friction, friction stability and wear) in dry or marginally lubricated conditions.

- Computational support: Via multi-scale and multi-physics models we perform a numerical analysis, including simulation of fluid- and particle-related tribological issues. Both lubrication modelling (elastic-hydrodynamic lubrication, smart fluids) and erosion/abrasion modelling (cavitation, droplet and solid-particle erosion) are performed, supported by multiple simulation techniques, particle-based methods and numerical optimisation tools.

Our unique software & hardware

- openFOAM

- STAR-CCM

- Various tools for lubrication and erosion/abrasion modelling, data analysis and interpretation that have been developed in-house

Customer Success Story

Development of a lubricant-free system for the ‘Eye of Dubai’, the largest Ferris wheel in the world. Our expertise in monitoring and characterising wear patterns in a broad variety of materials was a crucial component in this development.

Problem

The Eye of Dubai operates in harsh conditions (high temperatures). Moreover, with an axis diameter of 6.25m and weighing 1805 tonnes, a lubricant-free solution was required to ensure smooth operation. Due to the specific requirements, a customised solution had to be developed.

Solution

An international R&D team designed composite bearings based on a polyester matrix, reinforced with polyester fibres and using Teflon powder as lubricant. Flanders Make was responsible for material testing. In particular, large-scale bearing tests and numerical simulations have been performed. Our expertise in wear characterisation and material degradation paid a crucial contribution to the design.

Customer value

Together with various partners, a customised solution was developed to ensure the smooth operation of the machine to the customer.