LIBERTY - The automotive battery of the future

Imagine that you drive your electric vehicle from San-Sebastian to Barcelona, from Stuttgart to Brussels or from Eindhoven to Paris without the need of recharging it along the way. Then have it quickly charged without fear of eating into the battery’s remaining life. This is the goal of the EU research project LIBERTY (Lightweight Battery System for Extended Range at Improved SafetY).

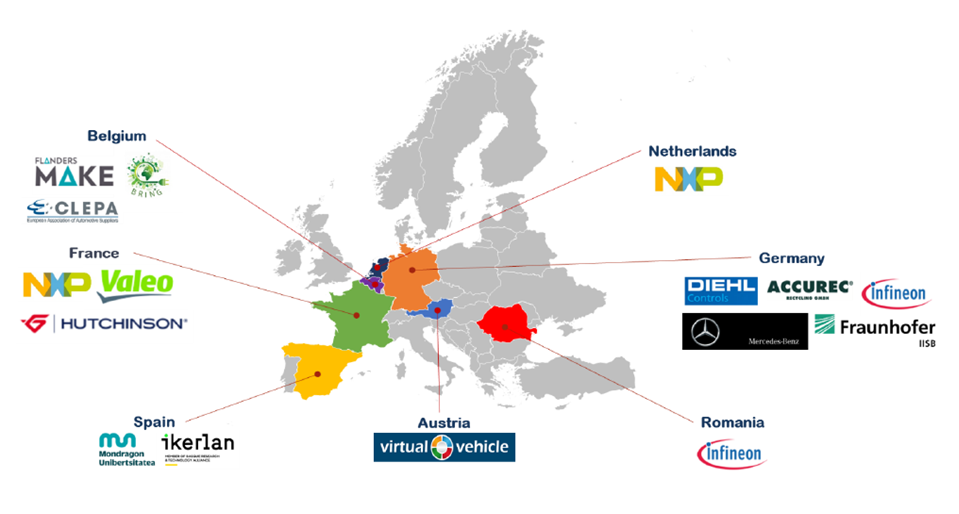

In this project we, together with 15 European partners, will develop a battery that provides its electric vehicle with the same useful life as that of current combustion engine driven vehicles: a range of up to 500 km, with an ultra-fast charging capability and an expected lifespan of up to 20 years or +300.000 km. This is a major step forward, as current batteries typically have a lower life span of up to 10 years or 150.000 km. To demonstrate the feasibility of the LIBERTY innovations, Mercedes-Benz AG will integrate the developed battery in one of its electric vehicles. Furthermore, the project considers a second life for the batteries. In situations where the demand on fast-charging, weight and energy density proves less important, the batteries could be re-purposed. For instance, to support a photovoltaic park or to store the energy generated in the solar panels of a building.

Key targets

The LIBERTY project will develop a new battery system through smart combinations and implementation of innovations, including:

- A compact and safe battery pack, based on high energy density cells and lightweight, crash-resistant housing.

- A versatile battery management system resulting in optimal performance and safety over the system’s total lifetime (first and second life).

- High accuracy state estimators allowing fast charging, enhancing range and lifetime and guaranteeing ultimate safety and diagnostics.

- An innovative thermal management system ensuring safety and preventing battery degradation during fast charging.

- Design a (semi-)automated battery dismantling procedure, thereby reducing costs of recycling and reuse.

- Development of future-proof testing protocols for standardised EV safety as well as performance testing.

Egoitz Martínez-Laserna, researcher in the energy storage area at IKERLAN and coordinator of the LIBERTY project, explains that, "this research will address many of the main barriers currently hindering the wider adoption of electric vehicles, as we work to address key consumer concerns such as the range of the vehicle, charging times, battery life, increased battery life cycle, battery safety and of course the considerable cost of the batteries”.

Role of Flanders Make

We are responsible for the following tasks within the project:

- Leading partner for the development of the test plan, including electrical, thermal, mechanical, performance and safety related tests.

- Executing functional safety and total-cost-of-ownership evaluations.

- Investigation of the hybrid approach (combination of testing and prediction modelling) for the accelerated life tests.

- Leading partner of work package 6: “Integration, testing and concept validation on cell, cell stack, battery system and EV level”. This includes:

- Performing power and durability tests on the modules and the complete battery pack.

- Final responsibility for all other tests (e.g., safety related tests) and the integration and validation of the battery pack in the demonstrator vehicle.