Setting up an IOT infrastructure is key to exploit the possibilities of digital transformation/Industry 4.0 implementations

Setting up an IOT infrastructure is key to exploit the possibilities of digital transformation/Industry 4.0 implementations

A digital transformation strategy with buy-in and support from senior management is important when implementing a digital transformation plan. This plan should contain actions related to the execution of pilot projects with a predefined return on investment (ROI) estimate and an estimate about the value-creating potential for the company of scaling up the pilot projects throughout the whole factory and within other factories of the company at other countries or locations.

The roll-out of these pilot projects is often impeded by the unavailability of a solid IOT (internet-of-things) infrastructure and related investments. Therefore, an IOT infrastructure should be considered as a key enabling element of each digital transformation/Industry 4.0 strategy plan. The IOT infrastructure is part of the OT (operational technology) environment and connected in a safe and secure way to the IT (traditional business IT network) environment. We will describe the main functionalities of the IOT further on in the text. But let us first highlight other benefits of having an IOT infrastructure available..

An IOT infrastructure:

- facilitates the collaboration between different departments within the company by having ONE common, shared and accessible environment to exchange data as well as dashboards for analytics and actionable insights derived from both;

- helps to install a digital culture as people who are trained in its usage will board the digital journey of the company;

- is needed for the future implementation and operationalisation of digital twins; and

- enables and facilitates the roll-out of new business models such as X-as-a-service.

You can compare the IOT infrastructure with “the internet”, which today enables so many things that we can no longer imagine a future without it.

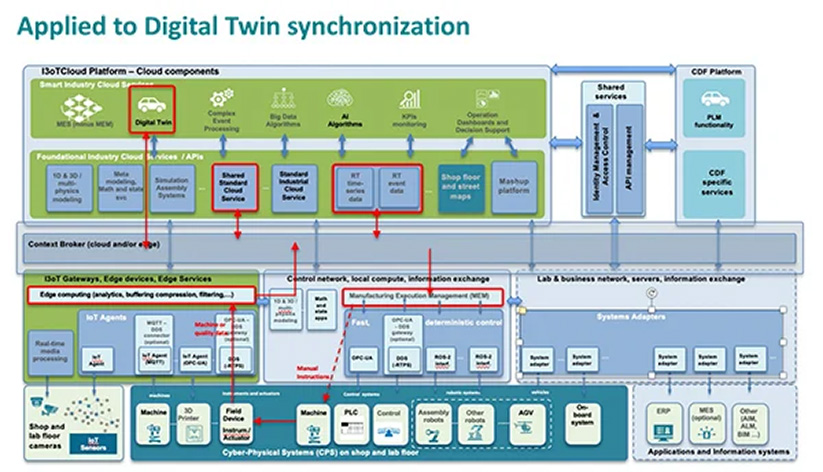

The following picture gives an overview of the high-level functionalities of an IOT (backbone) environment connected to the products (machines and vehicles) and production context as we will use it to support the research at different locations of the Flanders Make ecosystem and to serve as an inspiration for companies and other interested parties:

The Flanders Make IOT infrastructure is based on 4 main blocks/functionalities that are required for an environment enabling digital applications:

- Common safe and secure (data) platform for connectivity: It is a joint platform to be integrated in the company infrastructure, open for connecting future cloud infrastructure devices.

- Common & unified data storage: Cloud storage leading to fast and efficient collaboration between research partners at different locations.

- Common tool chain: Development tools based on cloud-native software reduce cost and effort for developing applications.

- Common environment allowing analytics for digital enablers, data sharing, running analytics, creating actionable intelligence-insights models and digital twins in the cloud with close-to or real-time feedback to experimental setups, real-time production or operation of unmanned vehicles.

Safe and secure connectivity is a prerequisite for creating trust in the IOT infrastructure and for promoting its usage by a large number of employees. Nobody wants to be confronted by a hacked environment and the potential loss of information, data, analytics, etc.

As all products and production processes, through the integration of ever more physical and virtual sensors, are becoming increasingly smarter, they are able to consider the context in which they operate and to use this information for improving their behaviour. All these sensors generate data that need to be smartly collected and stored based on data structuring. Sold machines generate data that might become available for future use.

To have a common and interoperable approach for data analysis processes, tools are needed that are available to everyone in the company, leading to a uniform data handling approach and extracting insights based on a common toolset.

Last but not least, the interim or end results that generate value to the company and its customers need to be available within a common environment. This allows collaboration between people from different departments and will generate overarching results that combine insights from R&D, engineering, production, maintenance and customer usage. This transparency is the embodiment of the digital corporate culture and allows the company to differentiate itself from competitors and to accelerate (a) product performance upgrades, (b) product developments and (c) the manufacturability of products, thus lowering costs and lead time.

To make things more concrete, we’ve added an overview of the implementation and intended usage of the IOT infrastructure for digital twins as shown in the following figure: