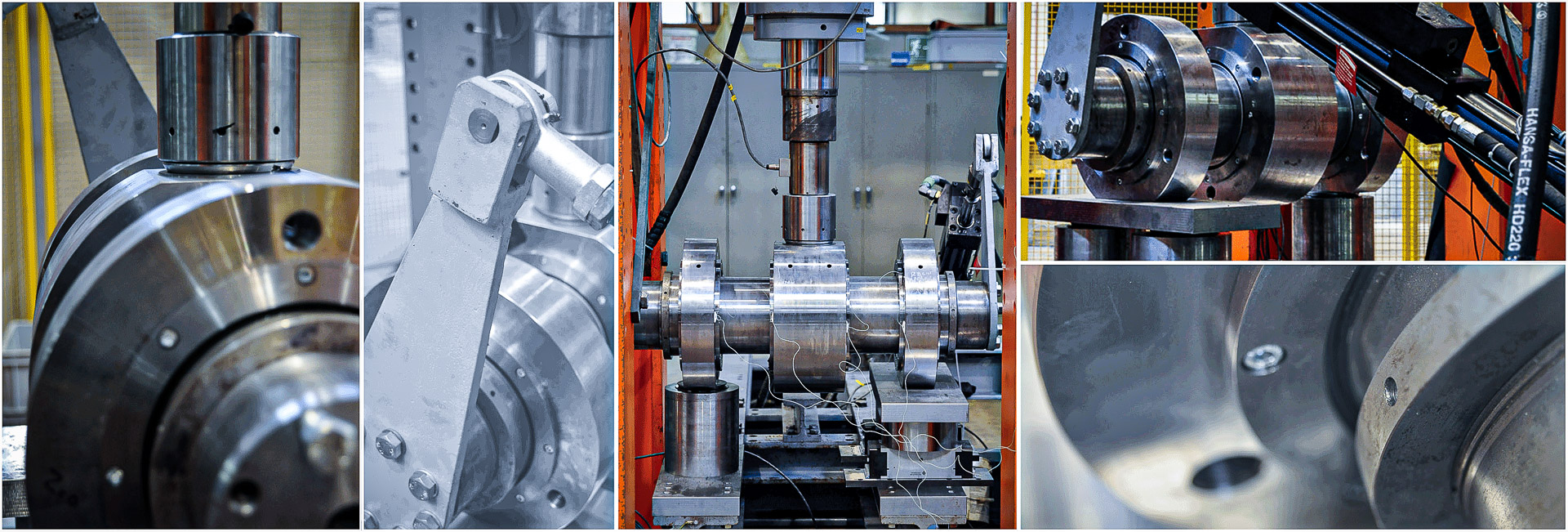

Test infrastructure for tribological characterisation

We provide services and test infrastructure to characterise the tribological aspects in motion products such as bearing elements, gears, cam rollers, and mooring chains.

Location: FlandersMake@.UGent

We provide services and test infrastructure to characterise the tribological aspects in motion products such as bearing elements, gears, cam rollers, and mooring chains. In addition to our standard laboratory-scale tribological test equipment, we can also do mechanical testing on a larger scale. We designed and constructed dedicated experimental tribological set-ups for dry and lubricated contact conditions, with contact loads that range from Newton to Mega-Newton.

In gears, bearings and cams, a combination of rolling and sliding is a common phenomenon. With our equipment, including several custom-made bearing test rigs and a dedicated back-to-back FZG twin-disc, we can investigate the friction and wear behaviour of different bearing and gear types. We can even include vision in the loop due to recent monitoring solutions.

What do we offer?

We offer test infrastructure to:

- Characterise the tribological response (friction, friction stability and wear) of bearings, gears, cams and mooring chains in dry or marginally lubricated conditions

- Large-scale mechanical testing (up to 6500kN contact load)