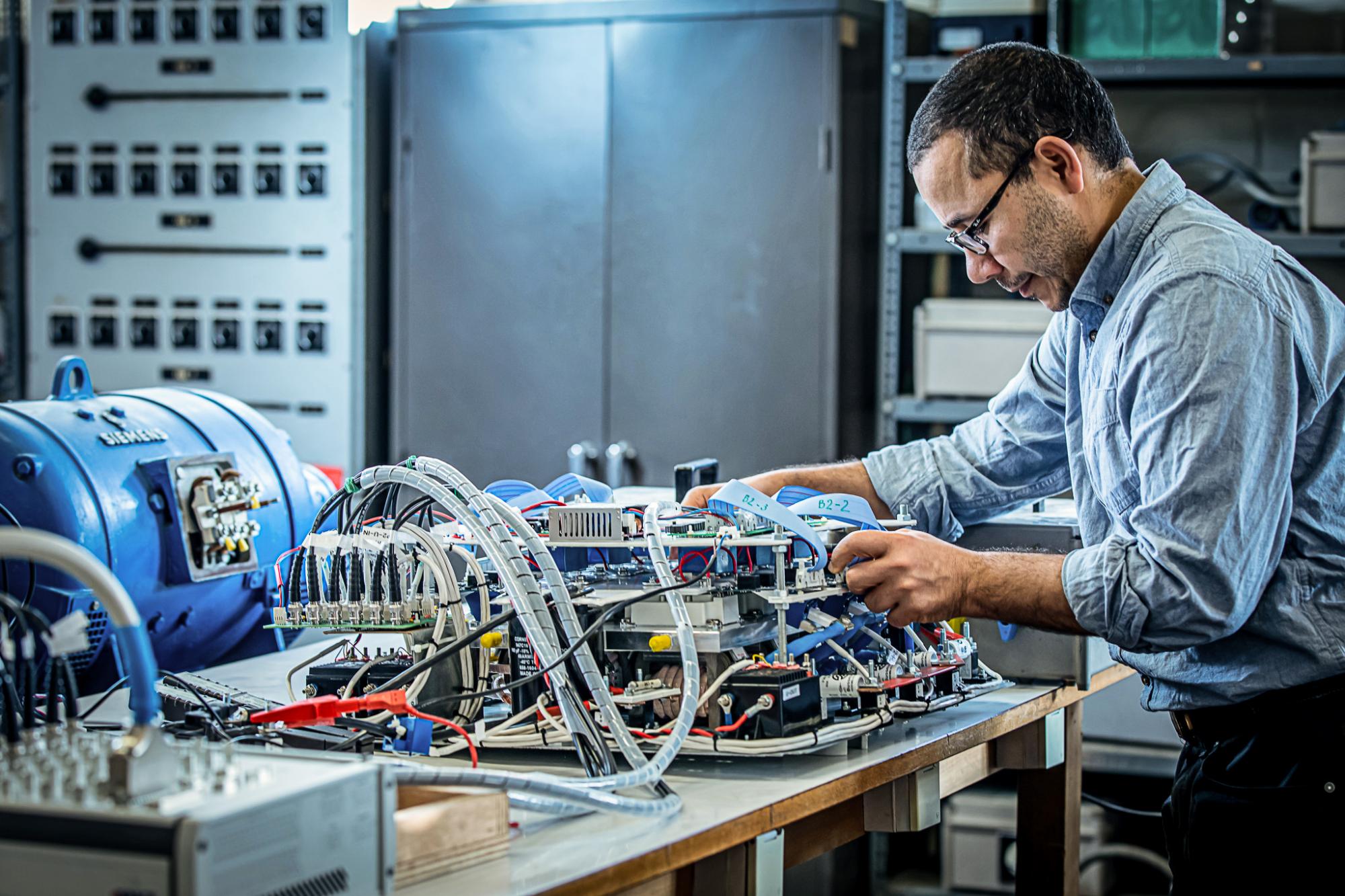

Design and prototyping of AC/DC, DC/AC and DC/DC converters

To improve the power density and reduce the total cost of ownership of machine and vehicle drivetrains, we offer customised design and prototyping of AC/DC, DC/AC and DC/DC converters based on our uniquely comprehensive experience in novel converter architectures, wide bandgap (WBG) semiconductors and advanced cooling concepts.

What do we offer?

Our services range from the design and prototyping phase up to the testing and validation of your customised power conversion systems:

- Designing, dimensioning, integrating, benchmarking and prototyping novel concepts, including:

- Novel topology exploration (e.g. multiport converter) & selection

- Technology selection (Si, SiC, or GaN) and sizing of optimisation

- Advanced (air & liquid) cooling concepts and thermal management control systems

- Multi-level Matlab modelling (based on proprietary Matlab models) and control design, including interactions between electrical, thermal, mechanical and control domains

- Design, modelling and control design of power electronics and control systems with a co-design approach (integrated sizing & control);

- Testing of:

- Power electronics with a wide operating range up to 350kW/600V and up to 160kW/1kV;

- Automotive charging and charging infrastructure in G2V and V2G modes;

- Conformance of charging systems (incl. standard testing and analysis communication protocol (PWM, PLC));

- Complete performance assessment of power electronics converters under controlled ambient conditions through highly accurate multi-channel data acquisition;

- High-accuracy measurement methods, developed especially for analysis of electrical signals described in IEC 61851-1;

- Testing and validation of control system units (CSU’s) and energy management systems (EMS’s) for vehicle drivetrains.

Customer success story

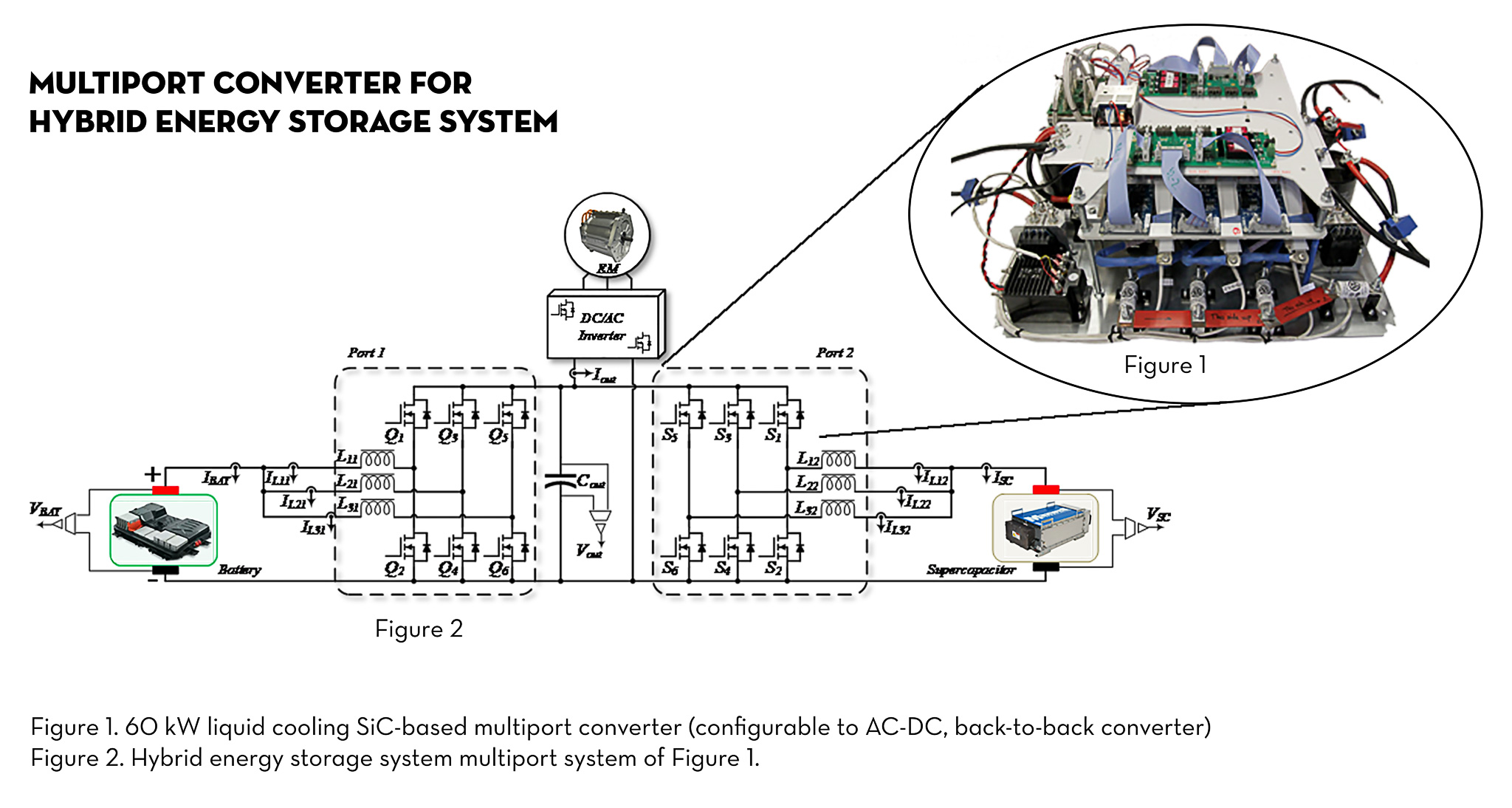

Scalable, flexible multiport converter system up to 200 kW and voltage levels of 800 V

Problem

Hybrid energy systems in electric drivetrain applications suffer from low efficiency rates, typically limited to about 93%, and large converter volumes.

Solution

- The introduction of Wide Band Gap (SiC) technology for high-power and high-voltage applications allows to increase the operational switching frequency from <20 kHz to 100 kHz, resulting in less converter losses and improved dynamic performances.

- System design optimisation, including control and thermal performance, with passive components and a downsizing of the cooling system.

Customer value

- Our solutions achieved a 98% efficiency at high operating powers.

- Even at low operating powers, we achieved a significant efficiency improvement.

- Reduced size of passive components.

- Reduced size of cooling system.

- Bi-directional power flow, configurable for multiple applications, including hybrid energy storage systems in electric drivetrains, grid-connected back-to-back inverters and charging systems.