WATEREYE - O&M tools integrating accurate structural health in offshore energy

Challenge

The cost of the energy produced by offshore wind turbines is affected by high operating and maintenance costs, which are due to two factors: lack of easy accessibility and harsh environmental conditions that cause high levels of corrosion.

In light of this problem, the Watereye consortium—formed by the Cobra company (an operator of offshore wind farms), Semantic Web (data management) and Delft Dynamics (drones) and five research centers, including project coordinator Ceit-IK4—will be designing an integrated solution that will allow wind farm operators to accurately predict future maintenance needs, thereby reducing operating and maintenance costs and increasing the amount of energy produced annually by offshore wind turbines.

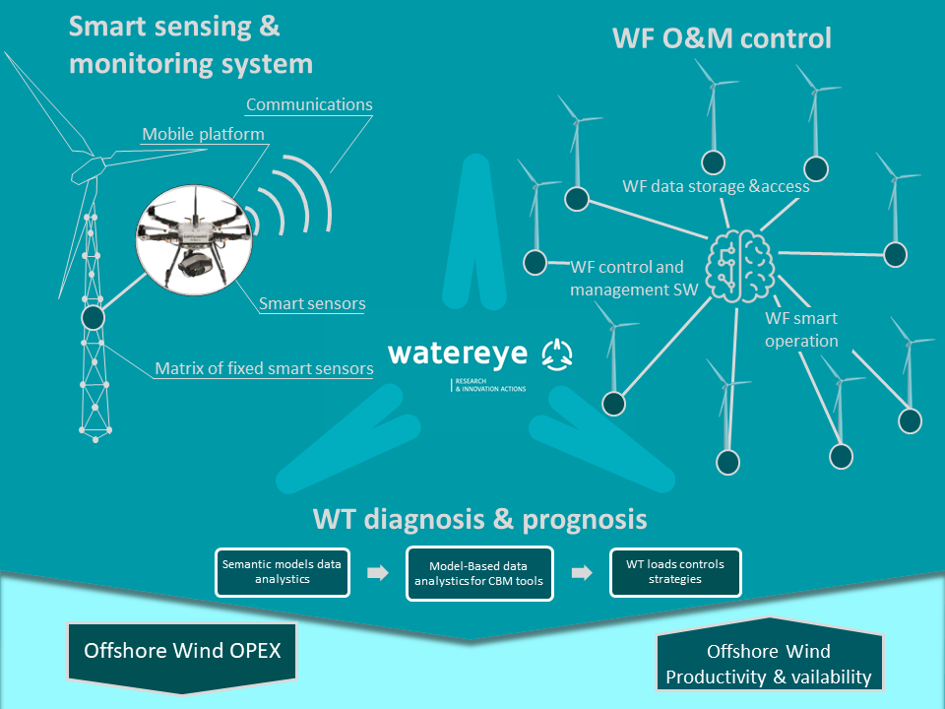

The Watereye project will design an advanced monitoring system that will make it possible to remotely detect corrosion levels at the most critical points of offshore turbine towers, which consist of the splash zone and the tower-platform junction. In addition to measuring corrosion levels, the system will be able to calculate the speed at which corrosion will propagate in the monitored areas. To monitor corrosion at a set of points, the measurement system will be incorporated into a drone equipped with a very precise positioning system. This system will measure from inside the tower the areas with the most corrosion and then wirelessly send the data a base unit installed in the wind turbine itself.

In addition to designing a low-cost, low-weight and low-power consumption measurement system, researchers will develop corrosion models that will process the measurement data such that the system will have the ability to learn and predict the state of the structure based on the corrosion data and other environmental parameters monitored in the tower. All the information collected will be used to run a diagnostic process which, when combined with a control system that limits the loads in the structure, will help wind farm operators to make the most efficient decisions regarding maintenance planning and overall wind farm control.

Project goals

The Watereye project will design an advanced monitoring system that will make it possible to remotely detect corrosion levels.

Economic value

O&M costs can account for up to 30% of the Levelized Cost of Energy (LCoE) for an offshore wind farm (WF). Deployment in deeper waters and farther from shore will increase O&M prices. Indeed, with an additional capacity of 1.558 MW in 2016, 338 new offshore wind turbines installed2, and a target share of the EU wind energy of 14% by 2020 and of 30% by 20303, the identification of structural risks and mitigation actions becomes a high priority for supplying electricity at cost- effective levels.

Smart O&M support systems could help attain the expected fall from the current LCoE of 11 €Cents/kWh to an LCoE of between 5.67 and 10.07 €Cents/kWh by 20354 of offshore wind energy thanks to the use of advanced sensing & monitoring systems, thus ensuring offshore wind approach to non-renewable levels.