SICK in SmartFactory

SICK Sensor Intelligence

From factory and logistics automation to process automation - SICK moves industries with sensor solutions. As a technology and market leader, SICK creates the perfect basis for safe and efficient process control, for protecting people from accidents and for preventing environmental damage using sensor intelligence and application solutions.

Networked production and control processes in complex machine environments define the future. With intelligent sensor solutions, we support dynamic, real-time optimised and self-organising industrial processes already today. Our sensors detect real operational conditions, convert them into digital data and automatically make the data available to your process controller.

As an innovation leader and pioneer in the development of groundbreaking sensor technology, we make Industry 4.0 possible with "Sensor Intelligence. Industry 4.0.

SICK's role in SmartFactory

Within the SmartFactory project, SICK provides the eyes of the machine and is the supplier of process data. From the sensor to the link to the PLC or cloud, SICK makes processes transparent. Within the 3 modules we use various sensor technologies that can be divided into different groups:

- Quality control and Track & Trace

- RFID technology for data transfer between the various modules and carriers that transport the various components. Here, IO-link makes it possible to implement very compact and cost-effective readers. This makes RFID a very accessible and reliable technology for Track & Trace applications in modern machine concepts.

- 2D-Camera in the storage module for identifying trays with a 2D code and checking the available parts in the trays. In this way an automatic inventory is possible and it does not have to be followed up manually by the operator.

- Smart Sensors via IO-link

- Especially the gripper sensors in the project offer new possibilities that were previously unknown to sensors. The MPS-G gripper sensors are equipped with an IMU that can provide additional data for diagnosis and automation purposes. For example, via IO-link these sensors can also provide information about vibration, acceleration, temperature, orientation, ..... This additional data makes it possible, for example, to detect malfunctions within the installation at an early stage and to anticipate them within the maintenance planning.

- Not only the sensors themselves play an important role, but also their link to the PLC and/or cloud. Within the screwing module we use the SIG200 IO-Link Master to integrate the IO-Link sensors within the Profinet network of the Siemens controller. This IO-link master can make the available sensor data directly available to the PLC on the one hand, as in this case via Profinet, but it can also be addressed in parallel via REST-API. This makes it possible not to have to intervene in the PLC platform and to make sensor data available directly in cloud platforms.

- Field Echo: to be added after implementation

- Safety

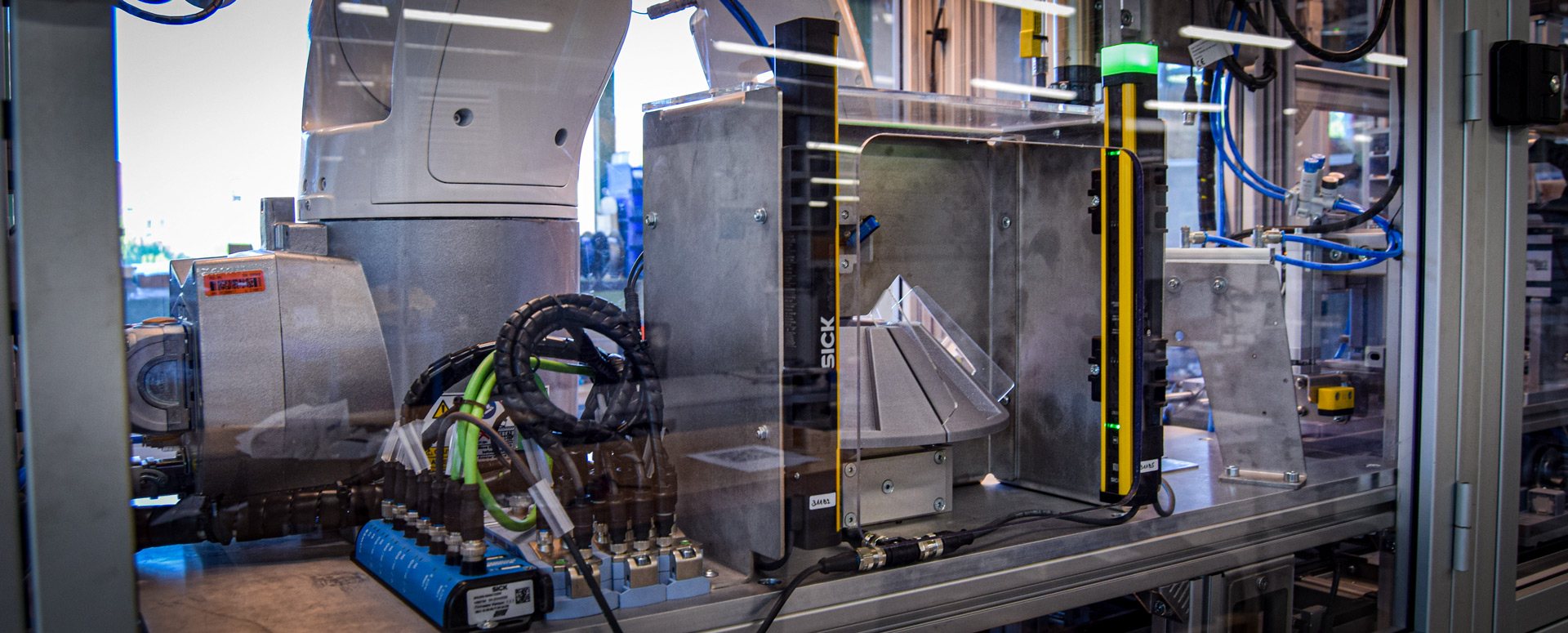

Safety is and will remain an important topic in industry. With flexible and dynamic machines and processes, this will only increase in importance. It is therefore of the utmost importance that safety is addressed at an early stage of the design process. With a well thought out safety concept, safety can boost the productivity of the installation by supporting the operator in his work rather than hindering him.At SmartFactory we opted for a relatively simple safety concept with mechanical guards protected by door switches. For the transition between the different modules RFID position switches and for locking the access doors RFID locking switches which only allow access to the machine when it is in a secure state.

To make it easy to hand over the finished product to the visitor, the screwing module is equipped with a light curtain that provides access to the finished product and puts the module in a safe condition when a hand is detected. This light curtain is also equipped with an additional IO-link output to provide diagnostic information such as the status of each beam in different quality values and thus quickly anticipate a possible misalignment or build-up of dirt on the optical lens.

Advantages of SICK in SmartFactory

Sensors are the prerequisite for transparent processes in industry 4.0. The sensor is thus the foundation of all subsequent applications. To sum up: without sensors there would be no industry 4.0.

Smart sensors, unlike their classical predecessors, deliver more than just measured data. Integrated decentralised computing power and flexible programmability are important features that make production more flexible, dynamic and efficient.

The clear definition of what data is needed and the compilation of this data in the integrated data world form the basis for reliable network communication. The selection of the right communication protocols for a defined path plays an important role in this respect. Ethernet-based solutions are in the foreground. But networking is also possible via IO-Link, especially for devices that require only limited communication skills.

In smart production, many sensors collect many data in many locations. This increases the importance of decentralised data processing. With additional interfaces in data or software systems, new analyses and functions are possible, increasing flexibility, quality, efficiency and transparency in production.