Adapted design method at Vitalo Industries

Adapted design method at Vitalo Industries

Vitalo Industries, located in Meulebeke, has more than 85 years of experience in the production of plastic and insulating parts. As one of the market leaders in their sector, they produce small and medium-sized series for various industrial sectors such as the medical, automotive and mechanical engineering industry. Their drive for innovation led to a Flanders Make membership in two of our competence clusters. In a previous research project, we had already developed an improved structural optimisation method. Together with Vitalo Industries, we have now investigated whether we could optimise this method for thermoforming, a production technique frequently used by Vitalo Industries.

Structural optimisation of a product design

When structurally optimising a product design, we first calculate the design of the mechanical structure based on parameters such as the loads/forces acting on the structure, but also its required stiffness, strength and cost. The optimisation programme that we developed in a previous project searches for the optimal placement of materials in a mechanical structure and takes into account corresponding design parameters such as thicknesses and dimensions. This multi-material topology optimisation starts from a mesh (.STL file) of the geometry of the mechanical structure and from a set of materials specified by the designer. The result is a design proposal that shows which materials are best used in which areas of the design. We have improved the existing optimisation method by allowing the possibilities and limitations of production techniques to influence the result. This enabled us to ensure that the calculated result is better aligned with the possibilities of the production technology used by Vitalo Industries.

Optimisation of thermoforming

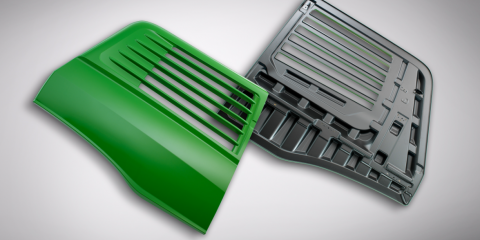

Production through thermoforming is a major business activity for Vitalo Industries. This technique is based on a flat sheet of plastic that is heated. After heating, the plastic sheet is formed by pushing a mould into the sheet and evacuating the air in between. After cooling, the material retains the desired shape. With this production technique, Vitalo Industries shapes large vehicle panels as well as the enclosures of industrial machines so that they are not only lightweight but also have the necessary stiffness.

The implementation of our optimisation tool on panels of agricultural machinery showed that Vitalo Industries could make its design for these panels 20% lighter. The necessary stiffness of the panel was thereby maintained and, in addition, the production cost could be reduced by 15%.

From theory to practise

A simple test set-up at Vitalo Industries should validate these simulations. Here, a wooden frame provided a representative representation of the structure in the machine or vehicle on which the thermoformed panels would rest or support. A simple load by means of weights and a measurement of the resulting deflection allowed to determine the stiffness. The results of this test set-up confirmed the above-mentioned predictions of the optimisation calculations. With these favourable test results and corresponding cost savings, Vitalo Industries was also able to convince their customer to roll out the adapted design. This also resulted for Vitalo Industries in no less than seven new orders, which – spread over the next five years – will increase the turnover of their 'thermoforming' department by 5% and will create additional jobs, both in their R&D and production department.

The collaboration between Flanders Make and Vitalo has ensured that we will design our products in a more cost-efficient way, while still meeting customer requirements. By combining Vitalo's technical knowledge with Flanders Make's project-based support, we have been able to thoroughly revise our design methodology."

Anne-Laure Lannoo - R&D Manager Vitalo Industries

Collaborations such as these demonstrate how Flanders Make can help companies to optimise their product designs, support their designers in making (critical) design choices, compare different product concepts in an efficient way and push the boundaries of a design, both technically and in terms of costs.