Optimal Design of Multi-Material Structures (OPTIMULTI)

Challenge

Combining the “right material at the right place and with the right geometry” (design) to achieve an optimal performance at minimum cost and taking into account specific design rules is very challenging because of the interdependent design variables involved (e.g. material types, shape, different constraints, different attributes, etc.).

Current state of the art design optimisation processes start with a topology optimisation, which searches for the optimal material distribution within a given design space to achieve a certain objective function, e.g. minimise weight, taking into account constraints, e.g. certain minimum stiffness. The most mature methods implemented in commercial tools and state-of-practice by industries are limited to a single material within one design space. Recently, some developments to support multi-material optimisation have been demonstrated on simplified use cases and very recently, one commercial tool has implemented multi-material optimisation.

However, all the optimisation methods and tools (both mono-material and multi-material) typically allow to consider only mechanical properties and weight as objective function or constraint (for instance to achieve a certain stiffness with minimum weight). Product cost can only be evaluated in a post-processing step by the designer. Besides, expert knowledge is often not exploited since design rules are not formalised into the optimisation algorithm often leading to unfeasible designs, for instance from a manufacturing or assembly point of view. These are main technological barriers when the aim is to develop a feasible product while balancing performance and cost.

Project goals

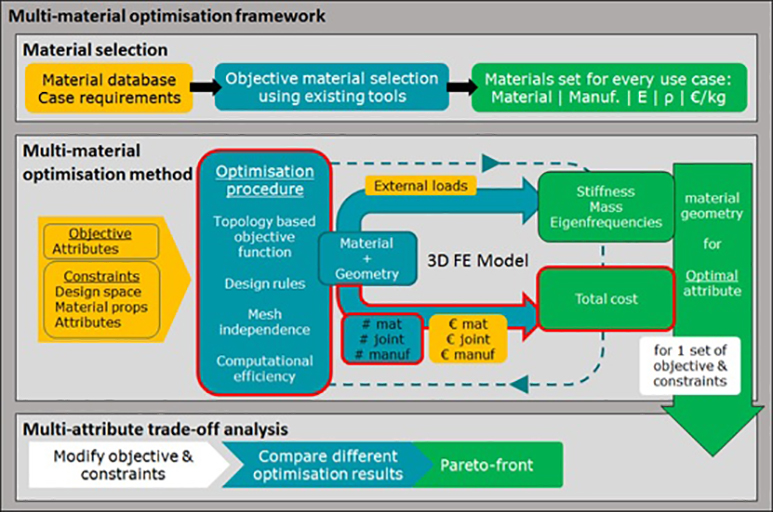

The general objective of the OPTIMULTI project is the development of an optimisation framework (methods and supporting tools) enabling to determine the optimal geometry and material choice, in the 3D design phase, in order to achieve the desired mechanical performance, weight and cost of multi-material structures as well as feasible designs by taking into account specific design rules. Based on the priorities set by the industrial consortium, stiffness and dynamic properties (e.g. first eigen frequencies) will be considered as mechanical properties in the optimisation framework.

To achieve this general objective, the following relevant and realistic goals are defined:

- Goal 1: Integration of a total product cost model in the optimisation framework enabling to concurrently optimise towards mechanical performance, weight and total cost as product attributes.

- Goal 2: Development and validation of a multi-material optimisation method, integrating specific design rules, enabling to concurrently and efficiently conceive feasible material choice and geometry (material distribution) using the product attributes (mechanical performance, weight, cost) as objective function or constraints.

Economic value

The envisaged optimisation framework will enable

- product developers and manufacturers to optimise performance, weight and cost of their products in a time and cost-efficient way.

- technology providers to extend their engineering services and tools portfolio towards multi-material solutions including cost estimation and design rules.

- material suppliers to enlarge their services for their customers towards system solutions, i.e. design and optimisation not of their own materials but in combination with other materials as well as design tailored to the specific customer application.

Demonstration

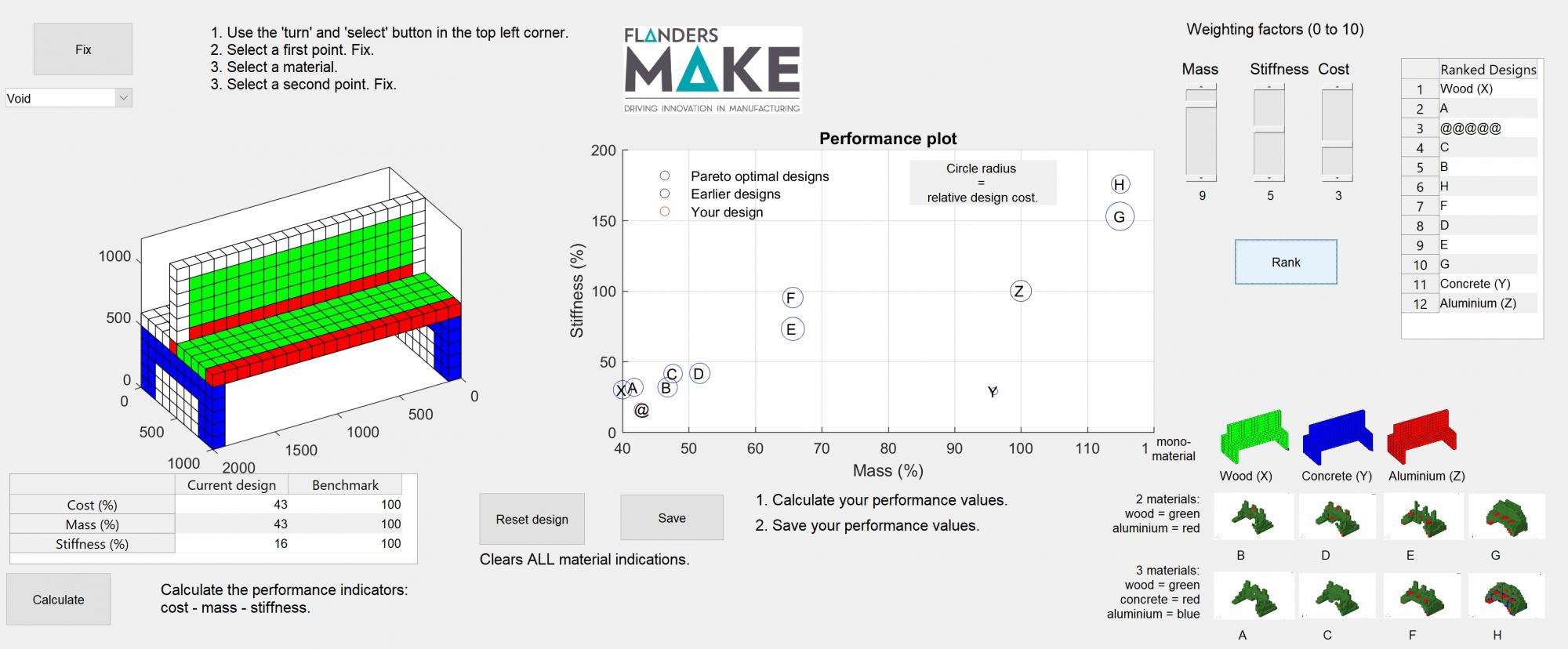

In the demo below you can design your own sitting bench. You can compare a structural analysis and a cost estimation of your design with these of some topology-optimized designs. The topology optimized designs are optimized for mass or stiffness and are composed out of two or three materials. You can also generate a ranking of the different designs depending on the weighting of performance criteria that you prefer.

(pasword for the demo: pypTNgQN6aEv)